28.06.2018 | admin | Bath accessories, Bath and health

Boilers in a heated water bath

The popularity of the baths as a place of rest and relaxation, hygiene and medical procedures is extremely wide. Almost every owner of a suburban area, be it a summer cottage or a cottage, strives to equip a bathhouse in addition to a house. Most of the amateur builders adhere to traditional canons - the construction of baths, independently heated with solid fuel and using the obtained thermal energy not only to warm up the bathhouse, but also to heat the water for washing. Therefore, the choice of a stove with a water heating tank is very important.

The principle of operation of water heating bath equipment

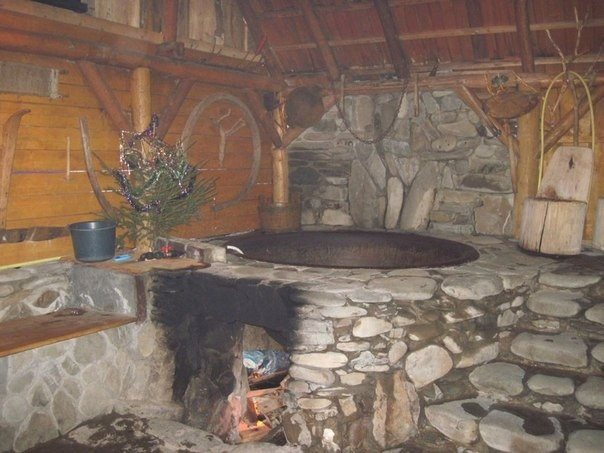

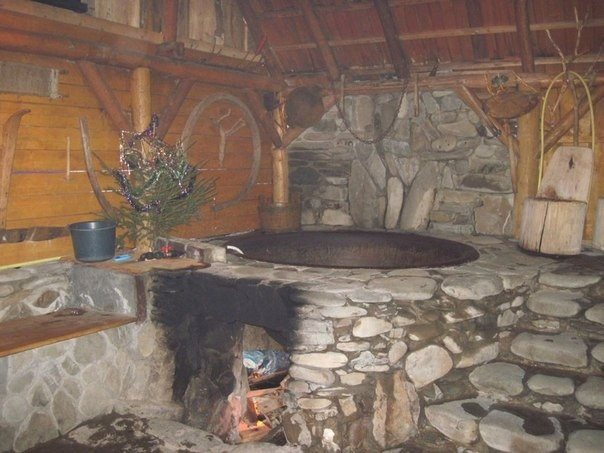

Adherents of traditionalism, who think of the bathhouse as a place of leisurely rest and a rather long stay, prefer the construction of stone / brick stoves, in which a tank / boiler with a capacity of 20-100 liters is built. The location of water heating boilers can vary considerably, depending on the design of the stove. The oldest are constructions in which the boiler is located directly above the combustion chamber, at the upper point of combustion of wood and the water in it heats up during the heating of the stove. A more modern design is in which boilers are used in a bath with heated water from sheet metal, usually it is adjacent to one of the walls of the combustion chamber or is located around the chimney. In this case, water heating also occurs only during the heating of the furnace.

The disadvantage of such structures is that stone, brick ovens with a high heat capacity are heated only once, before going to the bathhouse. The heat accumulated in the stone is enough to maintain a temperature of 60-90 ° C in the bath for several hours. Disadvantage - high consumption of fuel / wood and limited resources of heated water - one-time filling of the boiler. If water is used during the washing process, it is not recommended to add it to the cooling oven. This will rapidly cool the entire bath.

Much more popular are boilers for a bath with heated water of industrial or handicraft production, which are equipped with built-in water heating tanks or have them as attachments. The main advantage of such ovens is:

- Compactness;

- Low weight, which does not require foundation arrangement;

- High speed of heating the bath room;

- The possibility of heating water in the process of taking bath procedures, since the stove requires constant heating, otherwise it cools down quickly.

The location of the hot water tanks in such ovens is more varied:

- In the furnace body on top of the combustion chamber;

Tank in the furnace body

- A tank located around the chimney;

Samovar-type hot water tank

- A tank adjacent to one of the walls of the sauna stove;

Tank for heating water adjacent to the furnace

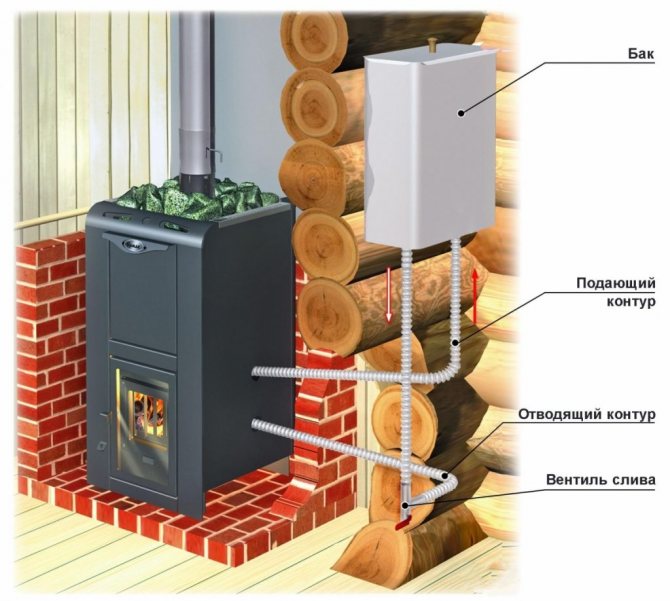

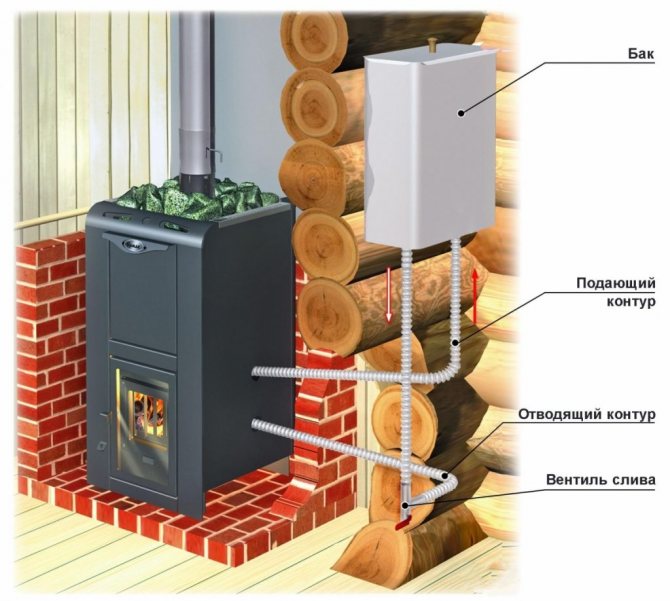

- Separately located tank connected to the furnace by a pipe system.

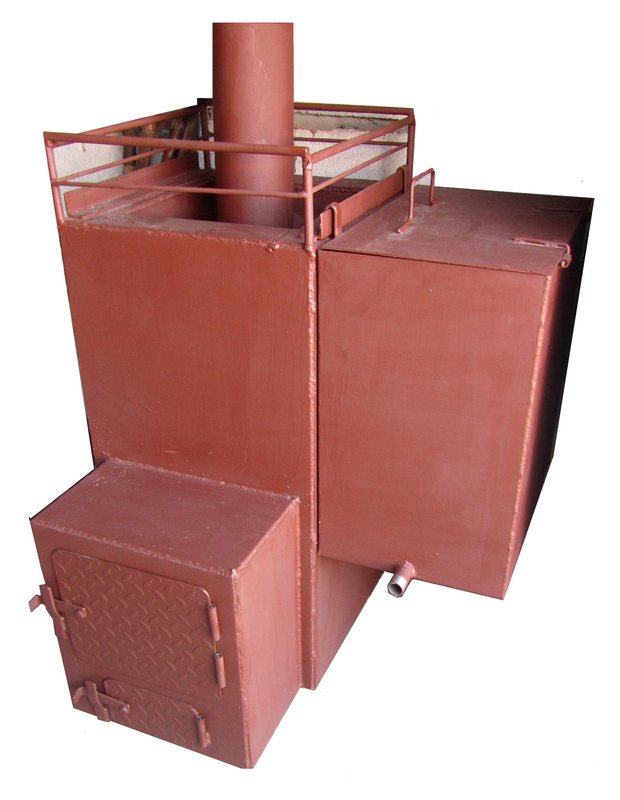

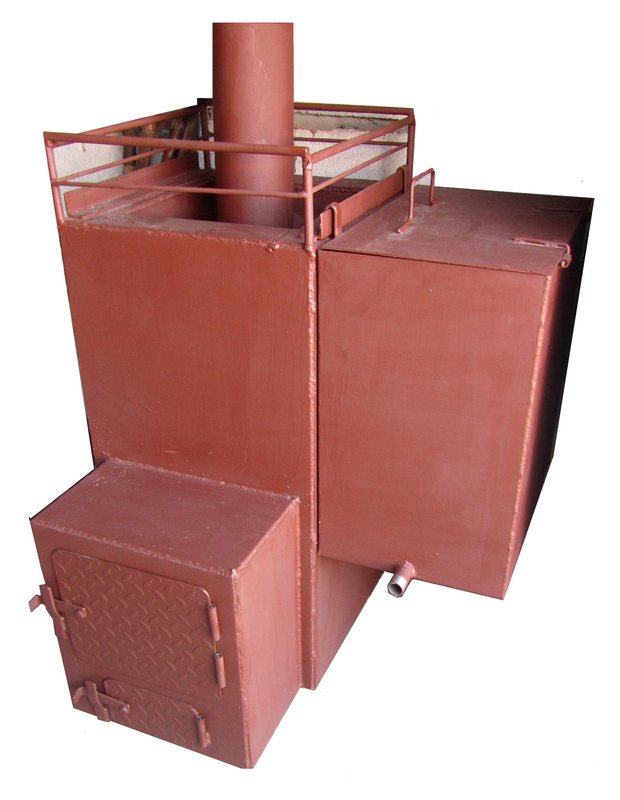

Freestanding bath boiler

Manufacturing options

There are several basic options for how to make boilers for a bath with your own hands. The drawings of the device must be made as accurate as possible in order to avoid various errors during assembly.

From a metal pipe

This method of creating a boiler is considered the most popular and most used. Most often, thick-walled metal pipes are used as the main material. It is best to use workpieces with a diameter of at least 50 cm and a length of about 1 m.With their help, you will get a device that can heat a steam room with an area of 9 square meters.

The boiler manufacturing process is simple and consists of the following steps:

- Three identical pieces with a diameter of 1.4 cm and a length of 30 mm are cut from the reinforcement. These parts will be used as supports for the product body.

- A circle (the bottom of the future device) of the same diameter as the pipe is cut out of a sheet of steel.

- A metal cover for the stove is cut from a bush of material.

- A hole is made in the middle. Its size must exactly match the diameter of the chimney.

- A hole is formed at the bottom of the pipe.

- Then the box is made. Inside it, a dividing piece must be provided, which will form two chambers: for the firebox and ash.

- At the next stage of work, the assembly of the structure begins. First of all, a manufactured box is welded, which should go out into the street or into the furnace compartment.

- A chimney pipe is inserted into the pre-drilled hole.

- Then the foundation for the furnace is equipped. It can be a concrete screed or a reinforced concrete slab.

- A device is installed on it, and heavy stones are laid on top of the lid.

- At the very end, a brick heat shield is built. You can make it in the form of a small wall or overlay the entire boiler.

From sheets of metal

This manufacturing option is distinguished by its simplicity and affordability. The work uses inexpensive sheet steel with a diameter of 5 and 10 mm, as well as some materials that can be bought at any hardware store in the city.

In order to independently weld a boiler for a bath from metal sheets, you need to perform a few simple operations.

Procedure:

- A drawing of the future product is drawn with a detailed presentation of the most important nodes.

- Individual blanks of the required size are cut from the purchased metal sheets. Moreover, they must exactly correspond to the manufactured scheme of the sauna boiler.

- A piece of thick-walled material folds over and forms the body of the device.

- Then the edges are welded to each other. In this case, it is important to make the seam as even and high quality as possible. If you do not have the ability or skills to carry out such work, then it is best to hire a qualified specialist.

- A piece of pipe is welded into the inner part of the manufactured body.

- Then the water tank is formed.

- A wide hole is made in the combustion chamber, a chimney pipe is installed in it.

- A special valve is attached to it, which will control the traction force.

- A combustion door is attached to the structure.

- A small pipe is attached to the back of the boiler for connecting a tap.

- A brick protective shield is built around the device. Thanks to him, the negative impact of high temperatures on people will be reduced. In addition, it protects against accidental contact and severe burns.

Making a boiler for a bath with your own hands is a rather difficult undertaking that requires a significant investment of time and money. With the right approach to business and following all the recommendations, you can make high-quality equipment that will work correctly for many years and please people.

Furnace selection and calculation of heat transfer from furnace equipment

The choice of stove depends on many factors:

- Bath foundation;

- The material from which the walls are made;

- Bath area, dressing room, other premises;

- Steam room ceiling thickness;

- The type of fuel on which the furnace will operate;

- The climatic zone and the time of the year in which the bathhouse will be mainly operated.

Few can afford the construction of large baths from thick coniferous forests, due to the significant cost and labor intensity. In addition, such a bath requires prolonged heating of the stove and, therefore, a large amount of fuel.Arrangement of the foundation for a stone oven in terms of labor intensity and time is no different from work on arranging it for a house.

Pyrolysis boilers

The most modern ones are considered to be more advanced modifications of long-burning boilers. What is the difference? First of all, in terms of price, the cost of such equipment is far from affordable for everyone. A great variety of different automation systems have been installed; unfortunately, there are not very many real benefits from it. In addition, the more additional equipment installed, the greater the chances that some of it will fail.

A pyrolysis boiler differs from a long-burning boiler in a slightly increased efficiency. Gases released during slow burning or smoldering wood burn out in a special hydrolysis compartment. Preheated air is supplied to it through separate channels and gases containing combustible compounds burn out in an additional chamber.

Practitioners do not advise using such boilers for baths, they cannot meet the requirements for the speed and temperature of heating the premises. And it makes no economic sense to buy an expensive pyrolysis boiler in order to use it in the usual mode of burning firewood.

Calculation of the heat transfer of the furnace

For these reasons, most builders of baths on personal plots are trying to build the lightest possible structure from a thin bar or brick, insulating and sheathing the interior with clapboard. For such baths, the correct calculation of the heat transfer of the stove is of particular relevance. In most cases, if it is not made by handicraft, the technical specifications (product passport) indicate the volume of the room (or area) that can be heated by such a stove. In this case, there are no problems with the choice. It is enough to use the calculator, entering the required values, to determine which oven is best suited.

It is much more difficult to comply with all the conditions when making a stove with your own hands. In this case, it is necessary to take into account:

- A combustion door will be located inside the steam room or outside;

- What material is the door made of and is it sufficiently insulated;

- The type of fuel with which the stove will be heated;

- The thickness of the attic floor and floors.

IMPORTANT! An important aspect will be the shape of the steam room and the location of the stove. In the event of its incorrect location, it is possible that unheated zones may form, especially under the shelves, in which cold air will accumulate. Free-standing water tanks should not be placed in such blind spots. Otherwise, a large amount of fuel will be spent on heating, and the water in them will quickly cool down.

Installation of a stove pipe in a bath

There are basic recommendations for installing the chimney. The flue gas temperature reaches 450-550 ° C. An ordinary metal pipe heats up red hot.

Safety standards stipulate that it is not enough just to isolate the stove from a wooden wall; it is required to protect the surface at the points of contact with the chimney.

Fire-prevention cutting is required in the places where the chimney passes through the floor slabs and the roof.

Choosing the type of chimney

Ceramic and insulated stainless steel sandwich pipes are used to connect the sauna stove. Each option has its own advantages and purpose:

- Ceramics - the chimney is used for internal connection. The pipe goes through the floor slab and the roof. The advantage of ceramics is durability, resistance to aggressive and acidic environments, almost complete absence of condensation.

- Sandwich chimney - both internal and external gaskets are provided. In the second case, the pipe is brought out into the street through the side wall.

The chimney sandwich and ceramics are assembled according to the type of constructor. Self-assembly is not difficult.To facilitate installation, manufacturers provide step-by-step instructions with a detailed description of the work.

All components used in the installation of chimneys must comply with the existing SNiP and PPB. It is not recommended to use galvanized and asbestos-cement pipes, and do-it-yourself fasteners.

all oven installation videos

The choice of material for the tank

The most common are sheet metal tanks:

- Cast iron;

- Stainless steel;

- Enameled.

Each of these materials has certain advantages and disadvantages.

Cast iron tanks - a classic of the Russian bath!

They are durable, do not corrode, have a high heat capacity and do not cool down for a long time, are easy to clean from dirt, and are resistant to shock and mechanical damage.

They can be built into the furnace body. The only drawback is the large weight, which creates a load on the oven and requires a frame or hanging from chains.

Cast iron boiler

The boiler for a bath with heated stainless steel water is the most popular at the present time. Suitable for the device of a water tank of any shape and volume. It can be located both inside the oven and outside. Ideal for freestanding containers. The durability of the built-in tank depends only on the thickness of the metal. The only drawback is the rather high cost of material and manufacturing.

Stainless steel tank

Enamelled tanks are used only as hinged or freestanding. On contact with fire, the enamel quickly cracks and crumbles. Not resistant to mechanical damage, although it has the most aesthetic appearance among other similar products.

Enamelled boiler-titanium

Tank size depending on furnace performance

Bath builders, striving to save on material and price, do not always take into account the real need for water for washing. This is especially true for young families with children. The water consumption for washing each next family member is equal to that for an adult. Therefore, already during the design, it is necessary to lay down the volume of the tank, especially for stoves that do not provide for constant fuel filling and continuous heating of water, which would be enough to wash all those who were washed in the bath + 25-50% of the minimum requirement.

IMPORTANT! The volume of the built-in tanks is especially critical. For furnaces with an internal arrangement of the container, its volume should not exceed ½ the volume of the furnace. Otherwise, the water in the tank will heat up for a long time. In furnaces with high heat transfer, there is a high probability of constant boiling of water, its evaporation and the creation of excess moisture.

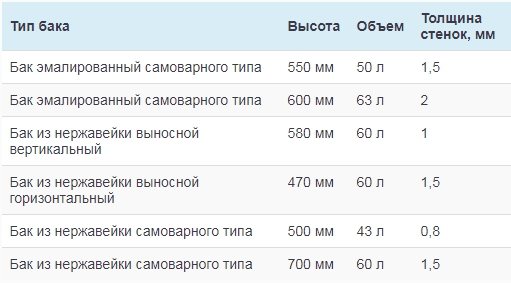

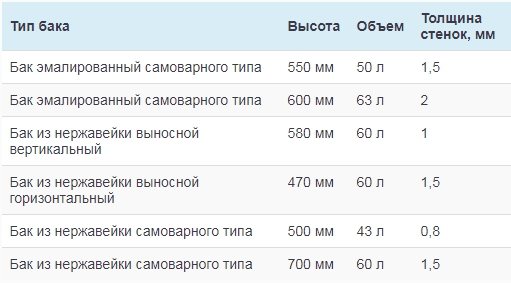

Tank wall thickness depending on volume

Varieties of heaters with heated water

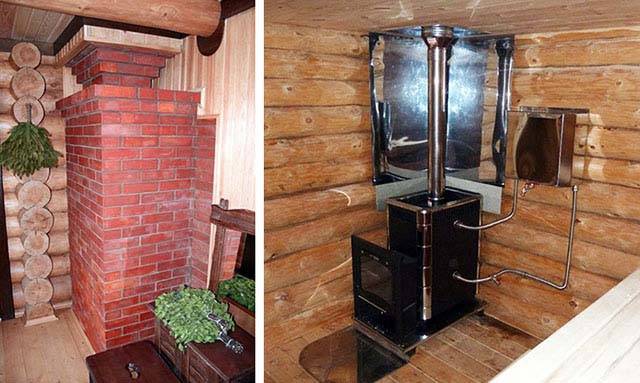

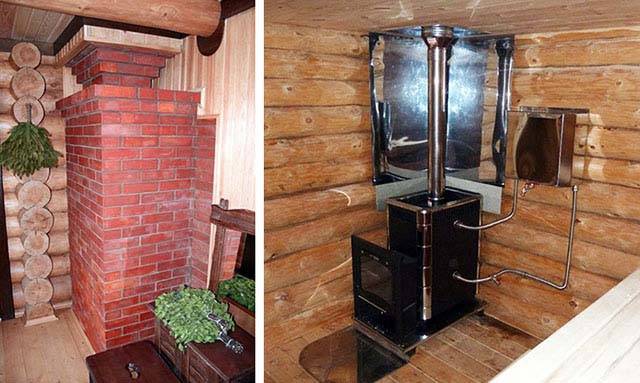

According to the material of manufacture, bath stoves are divided into 3 groups - cast iron, steel and brick. Metal products are sold ready-made, stone ovens are laid out on site. Let's make a quick comparison of these two categories:

- a brick heater will cost significantly more than a metal "brother";

- a brick stove is capable of heating all the premises of a bath, a steel stove - only a steam room and a dressing room (see the photo below);

- products made of steel or cast iron quickly warm up and cool down, a stone stove accumulates and retains heat for a long time;

- a metal wood heater is easier to install, a brick one needs a capital foundation and the hands of a good master.

The brick heat source is located in such a way as to heat all the rooms of the bath

Conclusion: the construction of a brick stove is appropriate at the stage of construction of a bathhouse building, designed to wash more than 5 people at a time. For a small steam room for 2-3 people. a steel potbelly stove with a remote firebox is quite enough.

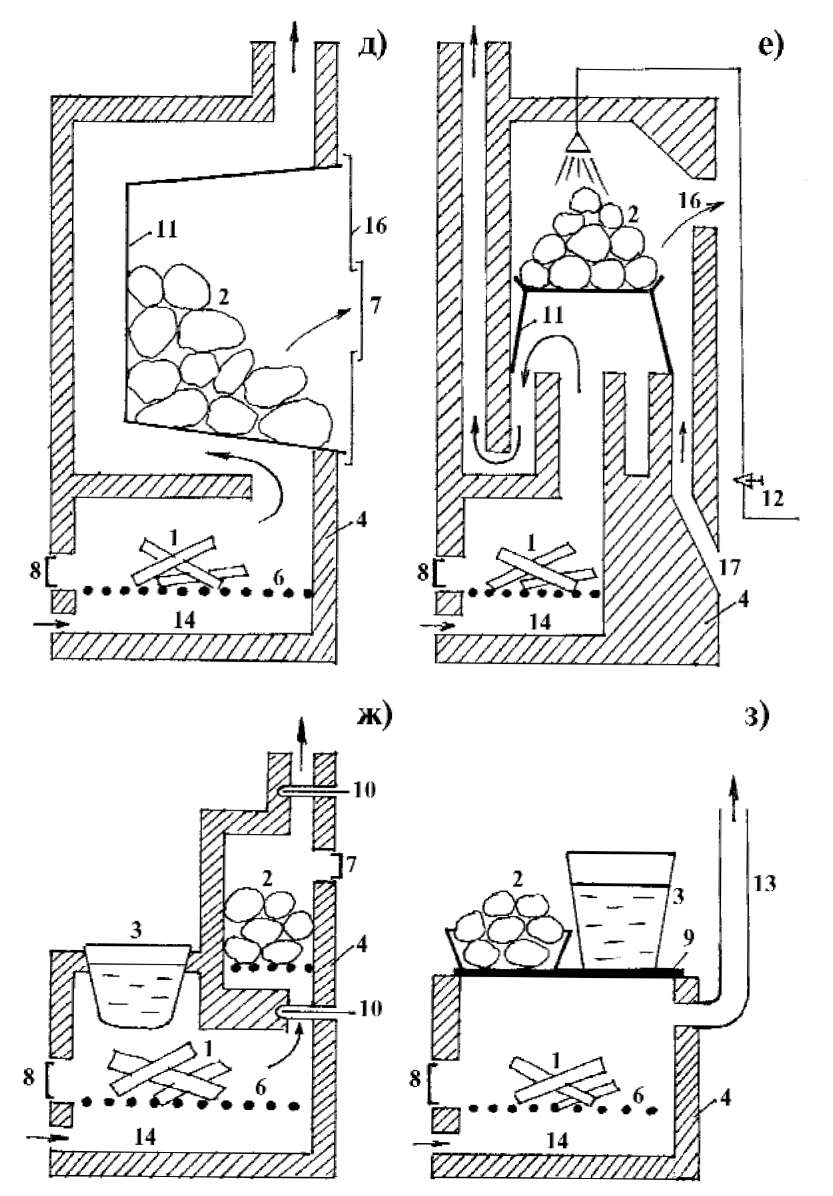

The water heating tank is combined with the stove in four ways:

- The hinged container is attached from the outside to the side wall of the firebox or placed on the body of a horizontal stove, filled through the top cover. Hot water is drawn from the tap or scooped up with a ladle.

- The cistern is built into the body directly above the firebox or stove.

- The portable tank is placed in the washing room and is heated by a water circuit mounted in the firebox.

- A separate container receives heated water from a samovar-type heat exchanger mounted on the chimney.

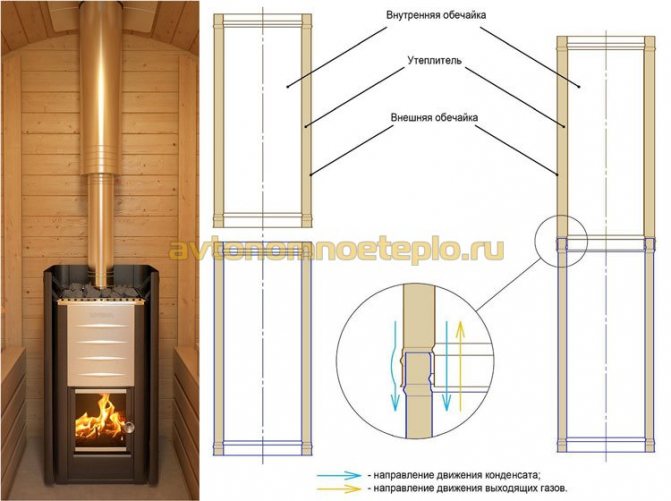

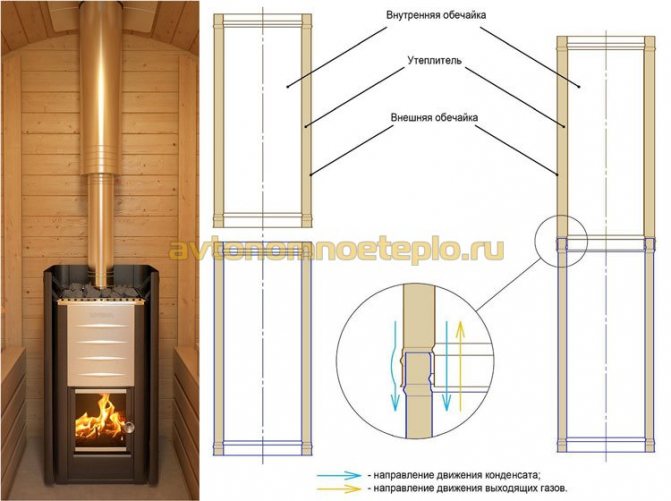

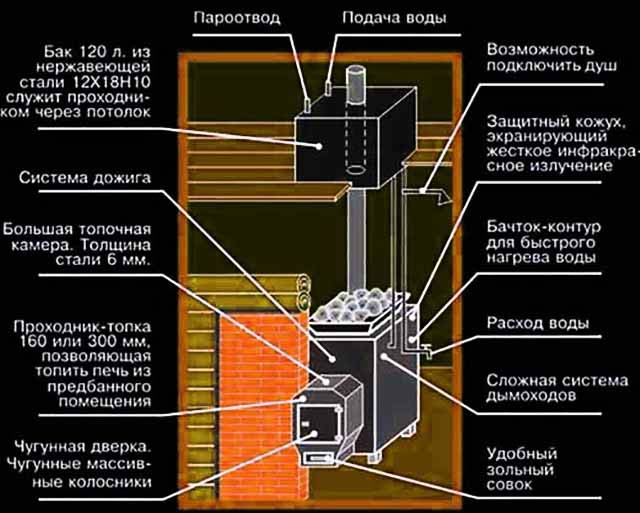

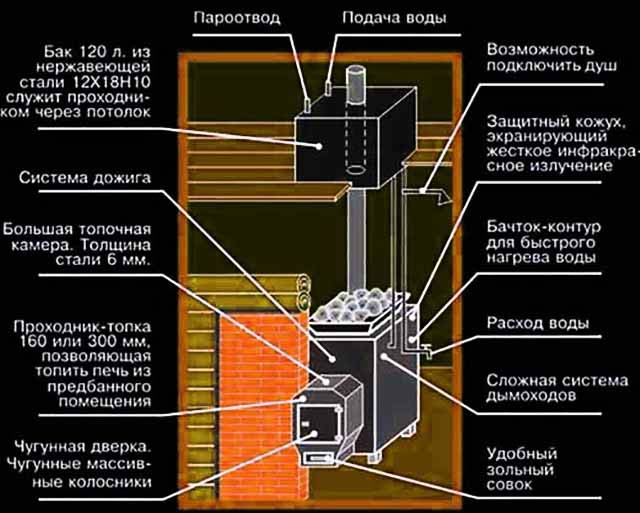

Note. Many manufacturers place a water boiler directly on the chimney and recommend installing it in a wooden ceiling opening, as shown in the diagram. The solution allows you to kill two birds with one stone: arrange a fire-fighting stove and create a natural pressure of water in the shower.

The tank built into the ceiling is heated in a combined way - from the chimney and the furnace heat exchanger

We propose to separately consider the pros and cons of each of the listed options.

Hanging containers

An open-type attached tank is considered the cheapest and correct solution for a traditional Russian bath, where a shower is not provided a priori. The design couldn't be simpler - a rectangular tank with a lid is welded from stainless steel and attached to the body of the furnace. The location of the tank is on the side wall, on top of the firebox or inside the heater.

Reference. The essence of bath procedures is the removal of toxins from the body that are released along with sweat in the steam room. The water heated in a hinged tank is at hand, diluted to the desired temperature and used to rinse the body. Water is scooped up with a ladle, repeated washing is done after patting with a broom.

A hanging cistern can be equipped with almost any wood-burning stove for a bath. A primitive option is a large saucepan or bucket with a lid, mounted on top of the firebox.

Options for placing the tank on a heat source

Disadvantages of stoves with attached tanks:

- the tank heats up much earlier than the steam room is heated;

- water must be constantly diluted in order to prevent boiling;

- the overhead capacity increases the dimensions of the stove, taking away the useful volume of the steam room.

Judging by the reviews of those who like to take a steam bath, not everyone likes traditional tanks. The modern user wants to rinse in the shower rather than pouring out of the ladle. Hence, it is worth considering other options.

Stoves with built-in tank

Heaters of this series are distinguished by a vertically oriented casing, divided into 3 compartments:

- firebox and ash pan located in the lower part of the body;

- the middle section is a closed-type stove equipped with a loading hatch;

- the upper part is a water tank equipped with a safety valve;

- the smoke channel leaves the firebox and penetrates the next two sections, heating stones and water.

Diagram of dry steam production in a stove with an internal tank

On top of the tank there is a lid for filling cold water, on the side there is an emptying tap. In some factory furnaces, the principle of a superheater is introduced - the vapors released during boiling of water are sent for additional heating from flue gases. The result is dry hot steam supplied to the sauna.

When it is required to stop boiling, cold water is added to the container. The production of dry steam is an important advantage of the internal tank over the hinged one. Plus, saving space in the steam room by increasing the height of the stove. Other options for placing the tanks are shown below in the photo.

The main disadvantages repeat the negative aspects of the attached tanks - too fast heating, the need for dilution and the selection of useful heat. There are also disadvantages of its own:

- it is difficult to sense the boiling point without a thermometer;

- the tank must be equipped with additional pipelines for water supply and emergency steam discharge;

- the weight and price of such a product is noticeably higher.

Variants of the integrated tank location: on the rear wall of the heater (left) and according to the type of boiler water jacket (right)

Water heating circuit and external tank

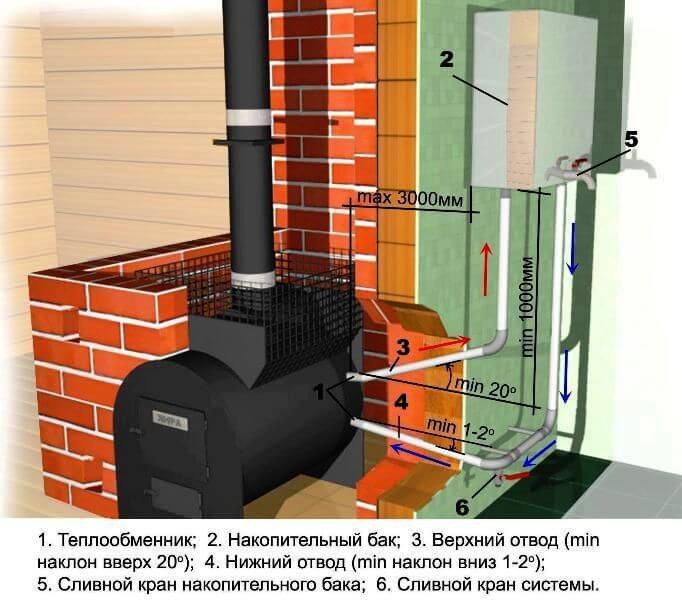

The heat exchanger installed inside the firebox of the sauna stove allows you to take out the storage tank with water behind the wall and organize washing under the shower without buying an electric boiler. The hot water supply device looks simple: the tank, suspended from the wall, is connected to the heating coil by pipes.

An important point. To prevent the internal heat exchanger from burning out, it is necessary to organize the extraction of heat in the only way - continuous circulation. If the distance from the stove to the tank does not exceed 2.5 m, pipes are laid with a slope for the natural flow of water, as shown in the diagram. Otherwise, a circulation pump will be needed.

Installation and connection diagram of a separate vessel

For the convenience of washing, you will have to pay with the following negative points:

- the DHW circuit takes away a lot of heat from the stove, increasing the heating time of the bath;

- you cannot operate the furnace with an empty coil - the metal will quickly burn out;

- boiling and vaporization in the heat exchanger is unacceptable - the heater will fail;

- if the piping of the heater is made of plastic, you need to monitor the supply temperature - the pipes can "float" and collapse from overheating.

Note. Built-in DHW coils are often used in brick-built bath and heating stoves. The heat exchanger is a register made of thick-walled steel pipes or a boiler is an iron tank placed inside the smoke channel (not in the furnace).

Furnace "Ermak" with a heat exchanger of the original design

A DHW system powered by a stove coil is quite viable and recommended by many manufacturers. An example is the “Ermak-16” furnace with a heat exchanger designed to operate with a separate tank with a capacity of 60 liters.

Samovar heat exchanger

The principle of operation of this water circuit is similar to heating water with an internal coil, the piping scheme is similar.

The difference lies in the location of the heat exchanger installed on the chimney and not inside the heater. The technical solution provides 4 important advantages over other options:

- The water heater does not affect the operation of the stove and does not slow down the heating rate.

- The element removes heat from the combustion products of wood, increasing the overall efficiency of the heating unit.

- The temperature of the exhaust gases is significantly lower than in the firebox (200-400 ° C versus 600-800 degrees), so the heat exchanger is not too afraid of boiling or accidental emptying.

- The chimney circuit can be purchased separately and fitted to any type of wood-fired heater.

A number of manufacturers, for example, the Varvara brand, offer sauna stoves with a water tank installed directly on the chimney. The container can be placed within the steam room and use water for rinsing, or you can build the container into the ceiling and lead the pipe to the shower room. In the second case, you will have to make recharge and drain through separate pipelines.

2 options for heating water from the flue - the tank is placed directly on the pipe or connected to a samovar-type heat exchanger

The only drawback of samovar heat exchangers (technical name - economizer) is the need for frequent removal of soot from the chimney. The DHW heater lowers the temperature of the flue gases, causing the settling of soot particles and tar. Under normal conditions, these pollutants simply burn out in a hot tube. For recommendations on choosing a product, see the video:

General conclusion. For a Russian bath without a shower compartment, simpler and more inexpensive options are suitable - stoves with an internal and hinged tank. The furnace coil is not a very good solution, the element serves much less than the stove itself. A chimney heat exchanger is perfect for heating the water in the storage tank located in the washroom of the sauna.

Tank location

The water tank located in the furnace body or on the chimney (samovar type) is suitable only for single-volume rooms of Russian baths with high humidity, in which high humidity is maintained at a relatively low temperature and in which they are simultaneously steamed and washed. For Finnish-type baths - saunas, the tank must be separately located, in the washing department adjacent to the steam room. Otherwise, each trip for hot water will require opening the doors, which will negate the effect of a dry room heated to a temperature of 90-110 ° C.

Do not neglect security measures. The tank should be located in such a place that there is no risk of burns when touching its surface. A high-located tap is also a source of increased risk of burns when drawing water.

The advantages of such designs

A traditional wood-burning stove with a water tank has the following advantages:

- Ergonomic and compact. Stoves for wood-fired baths with a tank, especially with a remote container and samovar type, take up a minimum of space and at the same time provide people in the steam room with everything they need: heat and hot water.

- Good aesthetic qualities. The finished ovens look very attractive and have a beautiful finish.

- Autonomy. Do not require any adjustments, just pour water and melt.

- High efficiency. One or two tabs of firewood are enough to warm up the bath and heat the water, provided that the power of the heating equipment is correctly calculated.

How to choose a boiler for a bath?

IMPORTANT! It is not an easy task to take into account all the nuances of choosing a boiler with a water heating tank, its location and optimal volume. When faced with its decision for the first time, inexperienced organizers of a bath are often mistaken. Therefore, the best way out is to resort to the services of a designer specializing in the arrangement of baths. This guarantees against the need to redo the internal heating system of the bath due to its low efficiency or inconvenience of use.