Advantages of a wood-fired boiler

When it comes to using firewood as fuel, we do not mean outdated stove heating, but modern high-quality equipment - solid fuel heating boilers for home use. Such units look beautiful externally, and also have a high efficiency - about 70-90%. This is because their design is based on the latest developments of scientists.

Many countries with cold climates are engaged in the production and sale of wood-fired heating boilers. Research is ongoing to minimize fuel consumption and increase equipment efficiency.

Compared to a gas one, a wood-fired heating boiler has a number of advantages:

- the price of firewood is about 1.5-2.5 times lower than natural gas;

- the installation of wood-fired boilers does not require obtaining permits from the gas service and the fire inspection, as well as notifying neighbors;

- subject to the purchase of a high-quality wood-fired heating boiler, it can also be heated with pellets, wood shavings and even coal;

- the design for wood-burning boilers allows them to work regardless of the connection to the power grid;

- the presence of automation in a wood-burning boiler allows you to reduce fuel consumption by reducing the frequency of downloads;

- often a wood-burning boiler is equipped with a hob that can be used to cook or heat food;

- combined wood-fired equipment allows not only heating the house, but also heating the water.

Reviews of household boilers for sawdust and chips: advantages and disadvantages

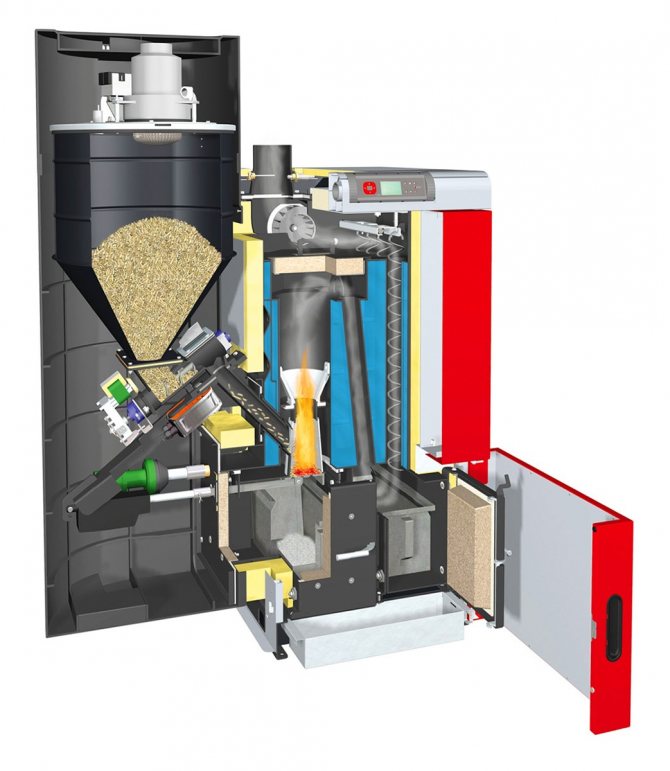

The owners of various household boilers on sawdust and wood chips in their reviews emphasize that most models of automatic modern units fulfill the manufacturers' promises, subject to their conditions.

In practice, heating boilers on dry chips and sawdust give out the declared power and efficiency. However, it is often necessary to burn wet fuel. The boiler unit can lose up to 30% of the nominal capacity for drying wet raw materials. We suggest sticking to the following recommendations:

- it is advisable to add raw fuel after the heating system reaches the specified mode;

- the content of wet sawdust in the total feed volume should not exceed a third;

- it is better to buy raw materials at special productions with an optimum moisture content of 20%.

Below is a summary table of the advantages and disadvantages of boilers for sawdust and wood chips according to our practice and feedback from the owners:

| Benefits | disadvantages |

| The design of modern units, equipped with automation, selects the most economical combustion process, taking into account the user's task, weather and raw materials within the range of 30% - 100% of the rated power | The boiler house consists of two rooms, equipped according to SP and PPB, occupies a large area of housing. It is safer to place equipment in a free-standing building |

| The manufacturability of modern models makes it possible to achieve indicators close to those when burning much more calorific types of solid fuels. As a result, the cost of 1 kW of thermal energy is less than that of pellets, briquettes and some types of coal. | The cost even for budget boilers with minimal automation is 3-5 times more expensive than solid-fuel automatic units comparable in power. True, it is worth noting that there are also cheaper universal boilers for domestic needs. |

| Low cost, availability and environmental friendliness of raw materials.Especially its price is low in places with developed woodworking industries, and for their own needs it is practically free (often enterprises are only happy to organize the sale of woodworking waste). | The organization of a warehouse for a seasonal supply of fuel requires serious investments in order to keep the humidity in the norm, not to violate the industrial safety standards and to automate the supply of fuel to the boiler room. |

| With all the complexities of the technologies and mechanisms used to achieve high results, the control of the unit does not cause any inconvenience. | Despite the increased level of equipment reliability, control must be carried out regularly and, if necessary, cleaned of soot and ash from the chimney and furnace, since the raw material may not always be successful. |

| Most of the maintenance work is accessible and easy. The installation of such equipment in a private house does not require the permission of the regulatory authorities. |

disadvantages

Of course, solid fuel boilers are not without some disadvantages. If you buy cheaper equipment, you will need to throw firewood into it every 2-4 hours. Therefore, you cannot leave him unattended. In addition, you need a place to store fuel, such as woodpiles or special sheds.

Heating wood-burning boilers for the home are sensitive to the quality of the fuel - the wood must be absolutely dry, otherwise the efficiency of the device will almost halve. Of course, high-tech equipment, equipped with automation for fuel delivery and temperature control, can cope with such a problem. However, it is quite expensive.

Let's consider in more detail the main types of wood-burning boilers based on the price factor.

How to choose a wood boiler

Important parameters

- Area and volume of heated rooms - affect the choice of the power of the unit. There should be 10 kW of power per 100 square meters, taking into account the power reserve - 12 kW.

- Heat loss indicator of the structure - determined by the material used to build the house, the thickness of the external walls, the area of the door and window openings.

It is better to entrust the calculation to a specialist. In case of financial difficulties, you can calculate the heat loss at home using special programs that are located on the websites of boiler manufacturers.

- Climate of the region - average temperatures in winter are taken into account.

- DHW requirement - determines the number of circuits in the system.

- Availability of electricity - influences the choice between forced or natural circulation systems. Allows to automate fuel supply and control of boiler operating modes.

- Type of fuel.

- Combustion chamber volume - determines productivity, fuel weight, length of firewood.

- Fuel combustion method.

- Heat exchanger material (steel, cast iron).

- Price.

Secondary parameters

The operation of heating equipment must be reliable and safe, therefore, secondary parameters include:

- unit design - parameter taken into account when installing the boiler in a residential area;

- combustion chamber depth - affects the size of the laid firewood, labor costs in preparation for the bookmark.

Low price segment of wood-fired heating boilers

First of all, it is worth considering a homemade wood-burning boiler for heating a house. Significant cost savings are achieved by purchasing individual components (sheet metal and pipes) rather than a finished product. Although it will not be so easy to assemble such a unit with your own hands, nevertheless, with proper execution and a successful choice of a model, the efficiency of a homemade wood boiler can reach 70-80%.

The simplest solution would be a standard bottom firing boiler design. It consists of a combustion chamber, an ash pan, a water jacket or register, a draft regulator, and a chimney. If you choose a more complicated design, then it can have all kinds of valves, smoke swirlers or mine combustion chambers. If desired, you can make a boiler even with an upper combustion type.

It is worth noting that the main disadvantage of a home-made boiler for heating a private house on wood is the high rate of fuel combustion. The boiler heats up very quickly, it gets very hot in the house, and after just a few hours the system cools down. To cope with this problem, some masters install a kind of battery - a container with water, in which they store a supply of warm water. It transfers heat evenly to the system and ensures a comfortable temperature for a long time. In some cases, the volume of such a container reaches 2-3 tons.

However, such options are acceptable only for those who like to work with their hands and have enough time for this. All others prefer to buy cheap factory products from domestic producers.

Please note that it is better to purchase a ready-made boiler not from folk craftsmen, but from trusted manufacturers with high-quality equipment and production facilities. The fact is that in an industrial environment, the quality of the fit of welds is much higher than it is possible to do at home. The method of painting and the quality of paints and varnishes are also important - heat-resistant paints designed for high temperatures are used in production.

As a rule, a cheap wood burning boiler has a simple structure and is made of sheet steel. It is desirable that its thickness is at least 4 mm. As for the power, it can be quite high - it does not affect the price. The disadvantages of equipment from the lower price segment are their service life and fuel consumption. Typically, factory products are designed for 5-10 years of work.

Nevertheless, subject to not very intensive use and free access to lumber, such equipment can be purchased.

Device and principle of operation

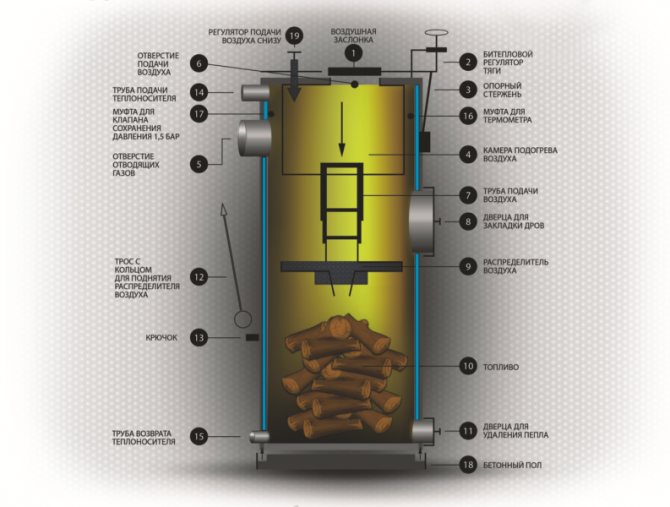

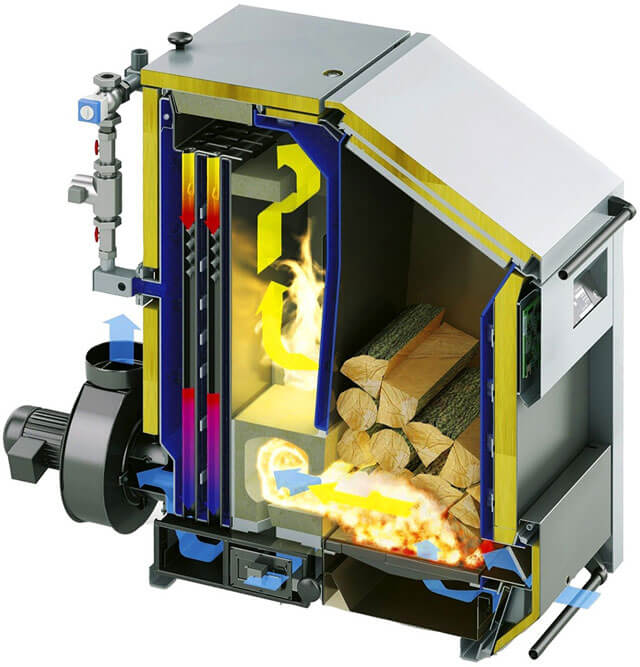

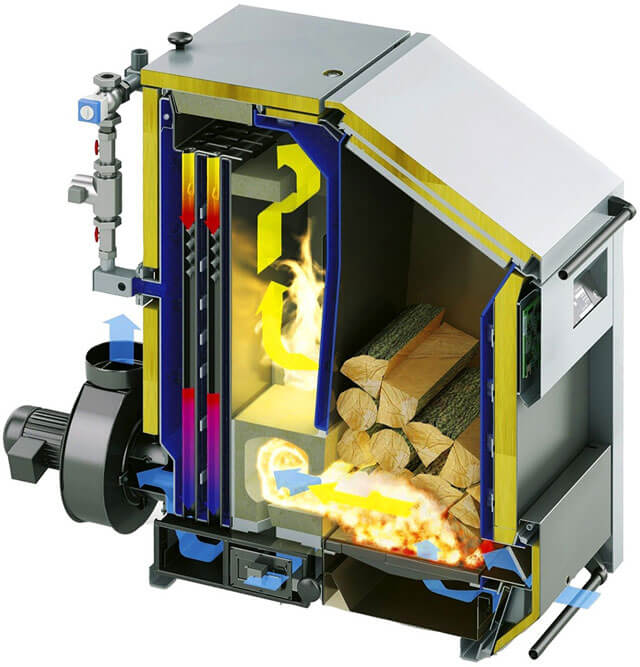

Boiler design

- Combustion chamber - the container in which the wood is burned. Firewood is put in through the firebox door.

- Chimney - serves to remove gaseous combustion products from the furnace.

- Grate - grate between the firebox and the ash pan. Serves as a basis for stacking firewood and pouring residual combustion products (coal, ash) into the ash pan.

- Ash pan - a chamber used to remove solid combustion products and to supply air through the shutter (louvers) into the firebox.

- Heat exchanger - an insulated circuit around the combustion chamber, in which the coolant is heated from the walls.

- Inlet and outlet connections - are necessary to supply the heating agent to the heating system, hot water supply and return (return) to the heat exchanger for reheating.

The number of one or two outlet pipes determines which type of unit belongs to: single-circuit or double-circuit.

- Thermal insulation - a layer of material with a low thermal conductivity, which is located under the outer casing of the unit. Serves to reduce heat transfer to the external environment.

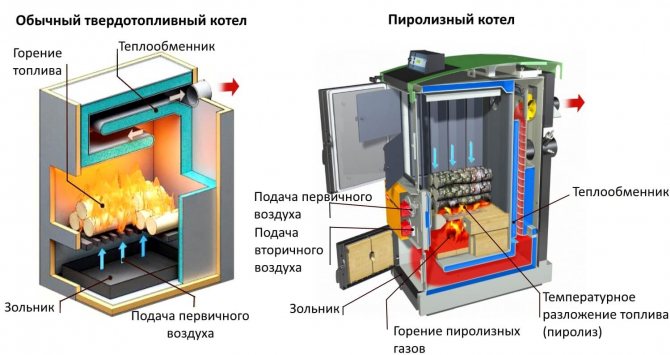

Fuel combustion methods

- No additional air supply - natural draft.

- With additional air supply by a fan, the power of which is regulated to change the intensity of heat generation.

- Pyrolysis mechanism of combustion - the fuel is heated in an environment with a small amount of oxygen, gas is released, which enters another chamber, in which it is ignited and heat energy is released.

- Long burning - wood burning direction from top to bottom.

The middle price segment of wood-fired heating boilers for a private house

Boilers from domestic manufacturers, as well as products from Germany, Lithuania, Poland, the Czech Republic and Slovakia, are presented to the buyer in the middle price segment. You can purchase a steel boiler for water heating on wood, the efficiency of which will reach 90%.Cast iron boilers are also found in this segment. Typically, their hulls are made up of whole sections, making it easy to assemble equipment on site. This design also simplifies the repair process by simply replacing the section.

Among the advantages of cast iron housings is their resistance to any kind of corrosion, which significantly extends the service life of the equipment. Nevertheless, cast iron is quite fragile - it does not withstand mechanical damage and temperature changes. Therefore, cold firewood cannot be loaded into a cast iron boiler.

As for steel, it is not afraid of mechanical damage and temperature changes. And provided that certain substances are added to the coolant, it will not be afraid of oxidation either. The main disadvantage of a steel boiler is that the steel burns out quickly. When choosing a boiler, make sure that it is made of heat-resistant metal.

When selecting the capacity of the equipment, it is worth leaving a margin of 25-30%. The fact is that the standard power value of 1 kW per 10 m2 is quite approximate and is applicable only for a pre-heated house with good thermal insulation. In addition, if a wood-fired steam heating boiler does not work at the power limit, then it will last much longer.

Rules for choosing a solid fuel boiler

Before choosing solid fuel boilers for long burning, their power should be calculated. On average, the specific value of energy consumption for heating a house with an area of 100 - 150 sq. m is 120 - 130 W / sq. m, for a house with an area of 400 - 500 sq. m - from 80 to 85 W / sq. m.

It is also worth paying attention to the various improvements that can greatly facilitate the operation of the equipment. So, for example, heating a country house with a solid fuel boiler can be controlled by commands from a mobile phone, if the boiler is equipped with a GSM module with a SIM card installed in it.

As a conclusion, we recommend watching an interesting video with a review on the operation of a cast-iron solid fuel boiler.

Long burning boilers

This category includes the most modern and economical units - boilers with a pyrolysis type of combustion. On one load of firewood, they can work up to 40 hours, and if coal is used, up to 5 days. The most reputable manufacturer of such devices is the Lithuanian one. Their boilers look beautiful externally, have an elongated shape and do not clutter up the room. The price of such equipment depends on the capacity.

The peculiarity of pyrolysis boilers is that in the process of burning wood, pyrolysis gas is generated, which enters a separate chamber. Burning out, it generates a large amount of thermal energy. Only after this does the solid fuel burn out. Thanks to this mechanism, pyrolysis boilers are the most economical and consume 1.5 times less fuel. Provided that very dry wood is used, the boiler can work without additional loading for up to 12 hours.

Best Wood Gas Boiler

Dual-fuel equipment is defined as combined (bi-fuel). Single-circuit and double-circuit are available. Differ in design:

- Single chamber - the burner is on top, the heat exchanger is located above the burner. The transition from one mode to another is done manually and requires frequent cleaning of the burner from soot.

- Two-chamber - the fuel is heated in independent furnaces, switching to the use of another chamber without stopping the heating process of the coolant is provided by automation.

pros

- profitability - low cost of wood (firewood) and gas, lower costs than purchasing two single-fuel units;

- interchangeability - alternate use allows you to prevent critical situations in case of emergency shutdown of the main gas, to distribute the use of one of the types at night, daytime.

Automatic gas connection after solid fuel burns out;

- high efficiency;

- autonomy - in the case of using a single-cycle boiler with manual switching to liquefied gas coming from the cylinder.

Minuses

- price - the cost of a bi-fuel boiler exceeds the cost of a single-fuel boiler;

- dimensions and weight (two-chamber);

- complex installation - it is better to invite specialists to install, configure and connect the equipment;

- the boiler is installed in a separate room, in accordance with the operating requirements due to the connection to the gas main;

- it is required to draw up and agree on a project for connecting gas equipment, control the connection by specialized services.