Why thermal insulation is needed and why you shouldn't neglect it

If you have already decided to break away from the bustle of the city and spend the winter time in your own country house, you need to thoroughly prepare it. Installing a heating system should not be the only activity. Good thermal insulation of a country house will help to significantly increase energy efficiency and significantly save on heating. In addition, living in a properly insulated house will be much more comfortable. The absence of drafts and cold walls is also more beneficial to health.

Which is better to choose

Basically, the choice comes between two main methods of insulation: external and internal. Ideally, the building should be processed both outside and inside, but in order to save money, you can limit yourself to one thing. The choice largely depends on climatic conditions, existing finishes, the chosen method and structure of heating, and available funds. So, if the internal premises are already fully decorated and there is still no possibility and desire to do new repairs, it is better to insulate the house from the outside. Correspondingly, you should act in the opposite case.

However, external finishing is more difficult to install, often more expensive and the possibility of installation is highly dependent on weather conditions. This makes it less suitable for cases where work needs to be done on a tight schedule. It is possible to insulate the dacha from the inside, even if the cold has already come.

External thermal insulation

First of all, when deciding how to insulate a country house, you should think about insulating the walls from the outside. The most common insulation materials for outdoor use are foam or expanded polystyrene boards and basalt wool. Today the building materials market offers a lot of other materials, but these are the easiest to work with, available and time-tested. Mineral wool is usually laid under siding, polystyrene panels can also be covered with siding, or covered with plaster and various decorative coatings. Today, these exterior decoration methods are the most popular.

If the house itself is wooden, then before starting any work it must be treated with special compounds that increase the moisture resistance of wood and reduce the fire hazard, as well as an antiseptic!

To compare these materials, consider an approximate installation scheme for both:

Insulation of a country house outside

If the exterior of the building does not have aesthetic or historical value, it is better to insulate the walls of the house from the outside. The thickness of the insulating material is determined based on thermal engineering calculations.

Three methods of external insulation are in demand:

- "Wet" (foam).

- Ventilated facade.

- Spraying (polyurethane or cellulose).

Insulation of country houses from the outside using polyurethane spraying is of dubious effectiveness, since it is difficult to accurately calculate the amount of the composition and apply it in a perfectly even layer. Although many builders claim successful experience with sprayed insulation, we will not recommend this technology.

The other two methods are effective only if the appropriate technology is followed. Consider how to insulate a garden house for winter living, depending on the material of the walls.

Concrete and brick foundations

It is advisable to insulate the walls of aerated blocks and cinder blocks with modern expanded polystyrene or polystyrene foam. This is the so-called "wet" type of thermal insulation system.

In this case, a primer is applied to the leveled base, glue and a plate of vapor-tight thermal insulation are applied to it, which is fixed with dowels. Further actions depend on the desired decorative finish; usually plaster or decorative stone is used.

This method is also suitable for insulating the walls of a brick house.

Wooden house

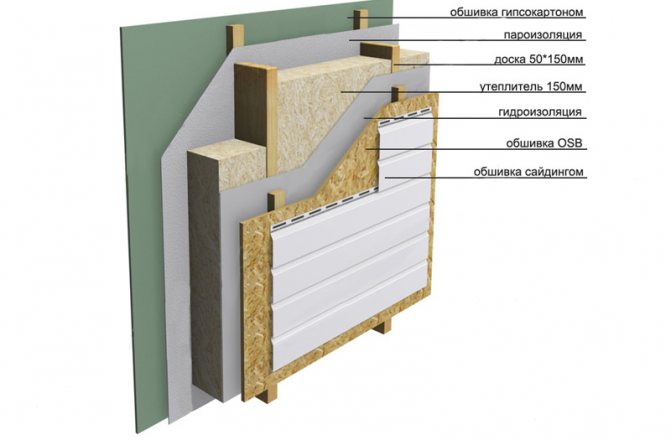

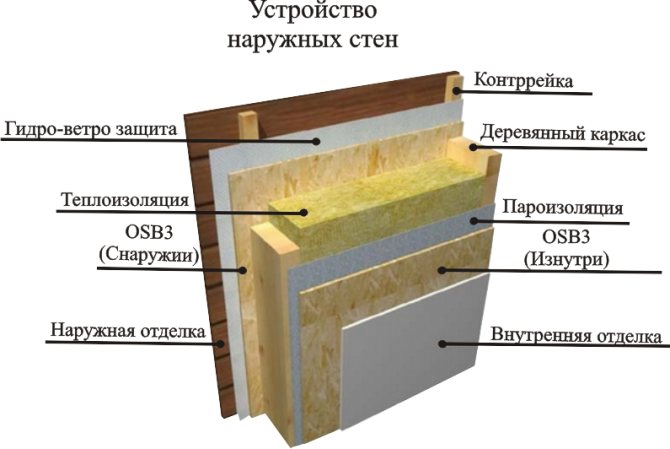

Most often, houses are built at the dacha from wood, usually conifers. To insulate a garden house for winter living, made of timber, use the principle of ventilated facades with a vapor-permeable insulation (mineral wool).

According to the technology, the insulation is attached close to the outer surface of the house and closed with an airtight membrane. Having departed from the last 2-4 cm, the cladding is mounted (siding, imitation of a bar).

The advantage of the method is the possibility of laying inexpensive insulators in the form of basalt wool, since here the heat insulator does not bear the load of the outer layer.

Technology features

The use of polystyrene with a ventilation facade is unacceptable, since the likelihood of material ignition increases in the air space. Polymeric substances are not used for another reason: condensation accumulates under them, which is why mold and rot will appear on the wooden walls.

If you insulate a garden house with your own hands using vapor-permeable heaters, the wooden base will allow moisture to pass in both directions, maintaining an optimal microclimate in the house.

Installation of polystyrene plates

For insulation with polystyrene panels, it is necessary to prepare the walls. They should be fairly even, without large distortions that can provoke breaks on the canvas. Also, the walls must be treated with a primer. The panels are glued and fixed on special dowels with wide plastic caps. You can also use special adhesives or those recommended for tiles. Then the resulting surface can be plastered and applied with a reinforcing mesh and a finishing decorative coating.

Read also: How to properly insulate a brick house from the outside?

Internal thermal insulation

Internal insulation of the premises is also carried out by laying heat-insulating materials under the decorative coating. Due to the fact that indoor conditions are much milder, the choice of materials and finishing methods is much greater. As well as for external thermal insulation, in order to insulate the dacha from the inside, the same insulating materials are suitable: mineral wool, foam or expanded polystyrene panels, and others. You can also use blown insulation.

The installation of the frame structure also begins with the processing of the walls themselves, depending on what they are made of. Be sure to treat the walls with a special compound against mold. When erecting such structures, it is not necessary to level the walls, this will significantly save time and materials. After the frame has been erected, a layer of foamed vapor barrier foil should be laid. It also has heat reflecting properties. If the wall is wooden, then you can fix the film with ordinary nails, but a construction or furniture stapler will help save a lot of time and effort. Then the heat-shielding material itself is laid directly, which is sewn up from above with sheets of fiberboard, chipboard, OSB panels, sheets of drywall, MDF panels or other materials. This kind of multi-layer sandwich helps to keep the warmth in the room.

It is imperative to first insulate those walls that are in contact with the street. It is permissible not to provide unheated rooms, such as balconies or verandas, with such thermal insulation if they will not be used in winter, but you should pay attention to the walls adjacent to such rooms.You can choose a thinner layer of insulating material for them if the veranda is warm enough. There is no point in insulating partitions and walls inside the house itself, except to increase sound insulation. Insulation of the outer premises adjacent to the house themselves will allow them to be used in the cold season and will increase the efficiency of heating the entire house.

How to insulate a garden house with your own hands

After following all the tips from this article, even a small stove in the house will be enough for the whole family to live comfortably in the winter.

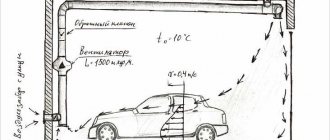

Approach your work responsibly in order to prevent cold bridges from being built in the structures. At the same time, do not forget to pay attention to the ventilation of residential premises, since insulation worsens the microclimate in the room, reducing the ability of structures to "breathe".

External thermal insulation of structures shifts the dew point towards the street, reducing the risk of moisture on the walls in the room.

Insulation of the garden house outside

Wall decoration can be done using the "wet facade" or "siding insulation" method.

Insulation of windows

When figuring out how to insulate a country house, in no case should you forget about the windows. Slots, improper installation, poor sealing can also cause heat loss. Of course, modern plastic windows with multi-chamber double-glazed windows filled with inert gases are the most effective. But it is not always possible to spend a decent amount of money to replace them. And sometimes some "upgrade" will not hurt new ones.

The choice of insulation

Before starting work, you need to decide on the type of thermal insulation. If you have basic building skills, the correct selection of insulation and knowledge of technology, most of the activities can be done by hand.

The modern market provides buyers with a wide range of materials that will help insulate a country house with high quality. Each of them has its own advantages and disadvantages.

The key indicators affecting what kind of insulation should be chosen are thermal conductivity, moisture resistance, durability, and fire safety.

There are several groups of thermal insulation materials:

- mineral wool;

- cellulosic;

- polystyrene.

Each of the above groups deserves detailed consideration.

Mineral wool

Mineral wool insulation, often referred to simply as mineral wool, is an inorganic fiber, usually porphyry. There is an air gap between the fibers, which occupies about 95% of the total volume.

The advantages of mineral wool are its high heat and sound insulation qualities, durability, environmental friendliness, fire safety. The main disadvantage is low resistance to moisture.

Cellulose insulation

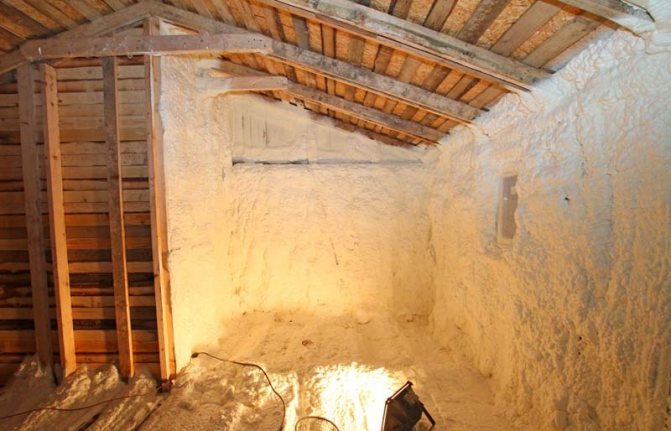

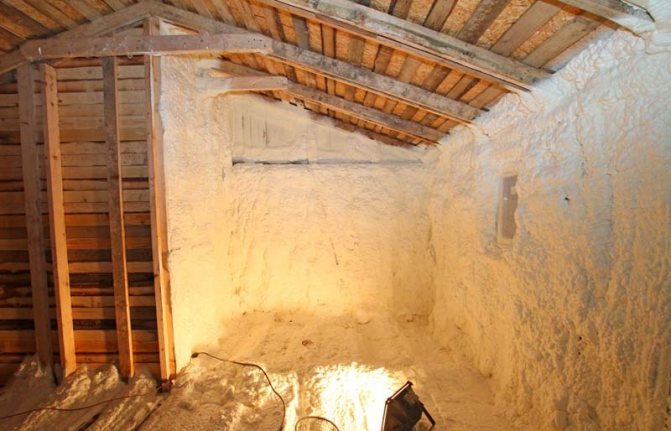

Cellulose insulation is made from recycled cellulose. The main advantages of the material are the low coefficient of thermal conductivity and the ability to fill hard-to-reach places for insulation; it fits well into any small cavities and gaps. Installation is carried out by spraying, manual or mechanized laying, backfill. Typically, such materials contain antiseptic and fire-fighting impurities, which makes them reliable in fires and resistant to rodents and insects.

Among the disadvantages of cellulose insulation are:

- strong shrinkage over time;

- when applied by a wet method, all metal elements of structures must be coated with paint or varnish, since corrosion may begin due to the long drying time of the material;

- high final cost of the thermal insulation system, since a large amount of insulation is required for high-quality insulation.

Polystyrene heat insulators

Polystyrene insulation, the main representative of which is expanded polystyrene, are granules filled with air. Due to this, the materials keep warm well. The granules have a cellular structure and therefore practically do not allow moisture to pass through. Expanded polystyrene is produced in the form of plates, which are very light and easy to install.

A significant disadvantage of this group of heaters is their instability to high temperatures, and, as a result, fire hazard.

Which is better?

The most competent solution to the question of which material to choose is the combined use of several types of insulation in different parts of the building structure.

Mineral wool should be used for thermal insulation of structures that are not subject to constant stress. Cellulose ones are better suited for warming facades, roofs, floors, and polystyrene ones - for foundations and basements.

Wooden windows

For a high-quality repair of wooden windows you will need:

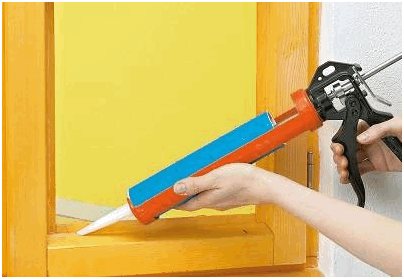

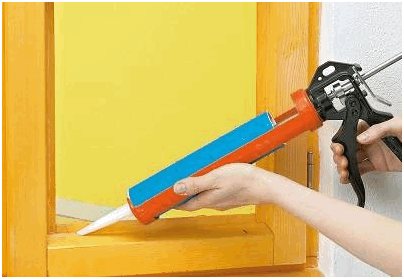

- Silicone sealant (if you take it in a special tube, you will need a glue gun);

- Polyurethane foam;

- Small spatula;

- Masking tape;

- Sealant;

- Unnecessary newspapers, magazines or film;

- Plaster;

- Nails (small, you can take furniture) and a hammer.

If there are broken or cracked glass, it is best to replace them. This also applies to glazing beads. First, remove any old sealant, loose pieces of plaster and cement from the cracks between the frame and the wall and from the ebb and sill.

Before filling the holes with polyurethane foam, it is necessary to protect the glass and the surfaces surrounding the window opening with paper or film, securing it with molar tape. It does not leave marks on various surfaces and can be easily removed even from wallpaper. Carefully place a small amount of polyurethane foam in the gaps. Keep in mind that its volume will increase several times during the day, so do not lay too much of it. After about a day, when the foam has completely hardened, you can remove the protective tape and paper. Now you can trim the excess. The most convenient way to do this is with a clerical knife. After that, you can level the surface with plaster.

Be careful when working with polyurethane foam! It is hardly removed from various surfaces and skin. Do not touch uncured foam with your hands! Avoid getting it on clothing, floor coverings, glass, frames, and other surfaces.

If it is not possible to dismantle the corners, glazing beads from window frames, then simply glue the cracks with silicone sealant. You need to plant the sealant as deep as possible in the holes. You can push it in there and smooth it with your fingers soaked in water. Thanks to this, the glass will not rattle and there will be no draft.

A special sealing tape must be glued to the joints of the sashes and frames. Self-adhesive are the most convenient. Before gluing, the surface must be cleaned and degreased. It is best to try to glue with a solid line without joints around the entire perimeter.

Construction of houses

54 votes

+

Voice for!

—

Against!

For many years, the townspeople have associated a garden house with a small summer building, which is assembled from scrap materials. With the advent of inexpensive building materials on the market, developers have the opportunity to quickly build inexpensive housing, which is suitable for recreation in the summer. And so that in a small country house it was warm even in the winter cold, you should think about decent insulation and heating of the garden house.

- Insulation of the floor and foundation

The need to insulate a garden house

As you know, the main purpose of a garden house lies in the formation of a recreational environment, that is, the creation of life support conditions in nature, which are close to home ones, for the effective implementation of the constructed plans.Many gardeners extend the gardening season until late autumn, and in winter they willingly come to ski and relax.

But such a pastime will often be impossible, and here's why. Country garden houses, as a rule, have a very simple design - a frame made of wooden beams, which is sheathed with clapboard. The inside of the house is finished with plywood, which, in turn, is pasted over with wallpaper. If you have not created proper thermal insulation in your summer garden house, it will be very difficult to keep warm in such a structure in winter, since the inner space between the casing is not filled with anything.

You can disagree and choose the option of heating with a temporary stove. However, in this case, you should remember that this is not for long. Fans of open fire need to know that the efficiency of fireplaces is low, it is only 10%, so it will not be possible to warm up like that. The warmth will be temporary, and a brick house, even for a short time, will have to be heated for a day or two. Therefore, you still have to think about thermal insulation. And meanwhile, it is not particularly difficult to insulate the garden house on your own.

Since the need for living quarters in winter will be less than in summer, in order to economically use thermal insulation and building materials, as well as to save fuel for heating, not the whole house can be insulated. In a garden house, it is enough to insulate one or two rooms, depending on the building area and the composition of the family. It is good if there is also a brick stove in the garden house.

Only in this case it is possible to spend weekends in early spring, late autumn and in winter and slowly redo all the upcoming work, for which it was not possible to carve out time during the summer period saturated with gardening concerns. Before proceeding to practice, remember that it is recommended to carry out all thermal insulation work when it is summer outside. If the cottage is two-story, or the living area of one floor is too large, you should also think about water heating.

Choice of materials

The most practical insulation materials are glass wool, polystyrene, foam rubber, foam insulation and fiberboards. It is possible to insulate the walls of stone or brick houses with the help of bulk materials that are placed between the double walls or use the latest liquid heat-insulating material for the walls. However, the materials used by our grandparents do not lag behind them.

Industrial heaters

For thermal insulation of a garden house, industrial heaters are most often used. Mineral insulation needs to be insulated from moisture. These include mineral wool and fiberglass. Mainly mineral insulation is used to protect floors and facades from the cold.

Mineral wool has been used in construction for many years in a row, it has proven itself in the best way, since it does not shrink, keeping its own technical parameters at a high level for decades. This material has gained its popularity due to the ease of styling and low price.

Cellulose insulation is mainly represented by ecowool, which is used to insulate facades, roofs and floors of country houses. Polystyrene materials or expanded polystyrene are needed when insulating roofs and facades, and they are also necessary when insulating foundations. You can insulate a garden house with such materials from the outside and from the inside.

Materials at hand

You can prepare some materials yourself. They are not inferior to mineral ones and are widely used in individual construction, insulation materials of an organic nature, such as sawdust, reeds, moss, sedge.You can add to them a whole list of insulating materials: chaff, straw, hay, small wood shavings, peat chips and others. In different regions of our country, there is still a lot of "foot" insulation. Coarse material must first be crushed, for example, chopped with an ax.

You can make the material for insulation yourself from improvised means that gardeners always have. This is plastic wrap and old newspapers. To insulate the garden house in this way, a film is placed between the sheets of newspapers and ironed with an iron. The resulting heat-insulating material is usually glued to the walls under the wallpaper.

Insulation requirements

For mineral insulation (mineral wool, glass wool, polystyrene), as well as small wood shavings, sawdust and moss, the thickness of the backfill should be at least 10 centimeters, and you can count on the outside air temperature to minus 20 degrees, if one sine qua non is fulfilled - a windproof outer cladding ... For more porous organic insulation, the thickness of the backfill should increase to 13-15 centimeters.

Mineral insulation must be compacted so that, after pressing on them by hand, the material returns to its original position. If the heat insulator is in mats, then it should not be loosened. Small shavings and sawdust are compacted to a dense state. It is customary to grind hay, straw, sedge, reeds, large wood chips for a start, chop with an ax, and the smaller the components, the better.

If you are interested in how to properly insulate a garden house and spend a minimum of money, then pay attention to the following information. To save expensive thermal insulation material and money, you can simultaneously use mineral and organic insulation, laying them like a layer cake, this is especially useful in those structures where you need to fill them in full thickness, for example, when insulating the floor or in the interfloor. It is recommended to lay a layer of the best insulation from the side of the cold source.

Remember that before use, any material must be completely dry, otherwise it will lose its thermal insulation properties, and organic insulation will also rot with all the ensuing inconveniences and troubles.

Warming a garden house

The pressure of warm indoor air in a garden house is always higher than that of cold outside air, so warm air strives to escape into the street. As you know, heat loss in any building, in particular in a garden house, occurs through the floor, ceiling and walls. Uncomfortable conditions occur if the difference between the temperature in the building and the temperature of the surface of the walls is more than 6 degrees, and the difference between the temperature of the air and the floors is 4 degrees. The best thermal comfort will be obtained with a temperature difference of 3 degrees. We figured out the reasons for heat loss, now it's worth figuring out how to insulate a garden house.

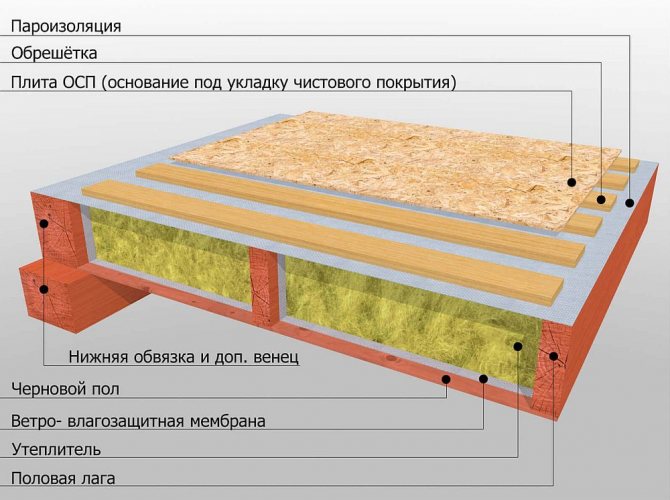

Insulation of the floor and foundation

The thermal comfort of a garden house will depend to a large extent on the construction of the floor. More often they represent one row of boards that are laid on logs, linoleum, chipboard, fiberboard are laid on the boards. Such floors are a common furniture base, but not an element of thermal insulation. From the ground, intense cold penetrates through these floors. Feet freeze from the cold floor, and even the high air temperature cannot save from this, since the temperature below is always lower than at the ceiling level.

If the house is built on a strip foundation, which is solid, then in the basement, most likely, there are air vents - special holes that are made to ventilate the space under the building. Such vents should be closed without fail. You can cover them with a piece of insulation, styrofoam, or an unnecessary rag.It is important to open such vents in the spring.

Nowadays, summer residents often buy garden houses ready-made. They bring a similar structure to the site, place it on pillars that act as the foundation, conduct electricity - and you can safely celebrate a housewarming. But it is worth noting that the under-house space in this case remains completely open. Therefore, it must be closed. And this can be done by making a filling.

Nail iron, rubber sheets or planks to the bottom of the house around the perimeter. Then cover it all with earth. As a result, an air cushion forms under the building, which will prevent the penetration of cold through the floors. In the spring, it is customary to clean up the earth or blow through, using, for example, pieces of plastic pipes that have a large diameter. Suitable are those that are used for indoor sewer systems.

To insulate the floor in a self-built garden house, the floor should be disassembled. You can use any available materials. Floor insulation is most often done in layers. To make the floor warm and dry, it must be torn from the underground without fail. For dry soil and low groundwater levels, limit yourself to boardwalks that are laid on logs. Supports will be low brick pillars, which are waterproofed with two layers of roofing material on bituminous mastic.

The brick pillars should be supported on a skinny concrete preparation layer. Under it must be a waterproofing layer of clay, which is pre-crushed with water, which will protect the structures of the floor and underground from soil moisture. Below is the compacted soil. A floor of such a construction serves for a long time without being affected by fungus and moisture.

Often, summer residents recommend insulating a garden house on the ground like this. Pour a layer of rubble, sand on top and compact this mass tightly. Place a layer of thermal insulator on top. Then it is customary to place the material for waterproofing and a mesh for thermal insulation, after which you can safely pour the concrete screed.

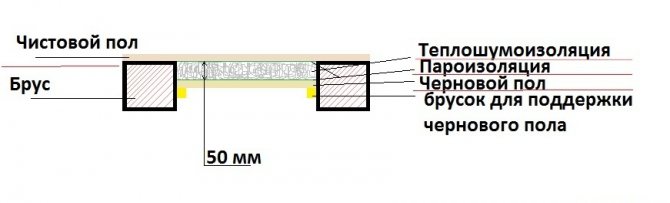

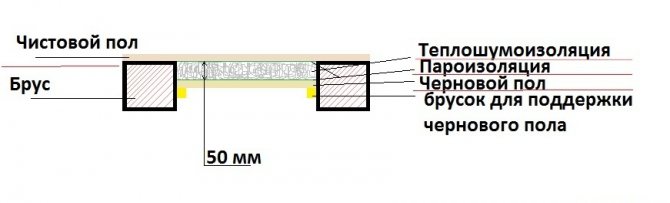

With a high level of groundwater, when insulating the floor in a garden house, it is customary to raise it above the ground by at least half a meter. In this case, the floor should be made double, with a heat insulator. As part of this option, summer residents do this: a rough floor (an old finishing floor is perfect for this purpose), a layer of heat insulator (expanded polystyrene or mineral wool) and a new finishing floor. The space between the rough and clean floor must be ventilated; for this, ventilation holes are made in the clean floor - in the corners of the rooms.

An important step in warming up a garden house is to protect the basement, if any, and the foundation. The choice of thermal insulation material for the foundation should be approached more carefully, you need to buy high-quality material, because it will affect both the thermal insulation of the building and the safety and durability of the supporting structures. Insulate all sections of the foundation, not sparing the material, because this way you can save up to 40% of the leaving heat.

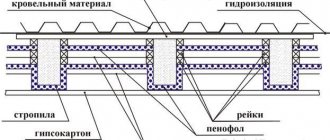

Insulation of floors

Carrying out roof insulation is of great importance, because almost 10% of the heat leaves through the roof. When choosing a roof insulation, you need to be guided by climatic features, the presence of snow and wind loads. Remember that the materials must be durable, moisture resistant, fire resistant, non-toxic, it is important that the heat insulator does not shrink.

The use of polymer materials for warming the roof of the summer residence will not be the most rational solution, because they differ in the properties of increased flammability, and you will need to take serious measures to increase the fire safety of the building. Following from all of the above, it is advisable to use stone wool for roof insulation.

In attic ceilings, it is usually customary to limit yourself to a vapor barrier layer, because the roof is most exposed to moisture in the form of precipitation. When the insulation is moistened, air is displaced from its pores and replaced by water. An increase in the moisture content of the heat insulator by at least 10% provokes a twofold decrease in the heat-shielding performance!

Frozen water worsens the properties of the insulation. That is why, when insulating a garden house, you need to pay attention to a reliable vapor barrier. The cheapest and easiest way is to make a vapor barrier layer from soaked clay in water. An alumina grease, which has a thickness of 20-25 millimeters, is applied directly over the ceiling boards.

Moss can be used as insulating material for the floors of garden houses. It is resistant to decay, perfectly absorbs water vapor and dries instantly. Moss, unlike other materials, does not cake over time and does not lose its own thermal insulation properties. In buildings that are insulated with moss, it will always be dry, and there is no musty smell. In order not to damage the thermal insulation material, running boards are nailed from above along the ceiling beams, which have a width of about 40-50 centimeters.

Wall insulation

Insulation methods for garden houses differ depending on the design. The very first method is external insulation, the so-called "pie" includes several layers: insulation, which is attached to the supporting structure, a reinforcing mesh based on an adhesive, and actually two layers of plaster. The second option: the thermal insulation material is attached using anchors with a hinge, then a welded stainless steel mesh is placed, and a thick layer of plaster is placed on the reconciliation.

You can also insulate the walls of a garden house with the help of hinged facades. The idea of such a design is very simple - there is an air gap between the heat-insulating material and the rain screen (the outer side of the facade), which allows moisture and water vapor to freely go out into the street, preventing the appearance of mold and mildew. Stone wool insulation is best suited for this purpose.

The greatest effect of the cottage warming procedure will be obtained when the walls are clad on the inside with sheet material - hardboard or plywood, laid on a crate made of wooden slats. Pave the space between the "new" and the brick wall with glass wool, or fill it up with tightly rammed sawdust, nailing boards horizontally. It is recommended to wrap a log house with mineral wool and sheathe it with siding or clapboard.

You can use the insulation material in any combination. For example, the lower part of the walls, where the boards are located vertically, is conveniently insulated with non-loose materials that lend themselves well to compaction in any direction (glass wool, mineral wool, moss, sedge, reeds, hay, straw, hay), and the upper part, where the boards are placed horizontally , can be protected from cold and bulk materials (small shavings, sawdust).

Such a wall will quickly warm up due to its low mass, while too thick boards, with all the seeming advantages at first glance, have the worst thermal properties. Heating them to a comfortable temperature in cold weather will require a lot of heat. And one more prerequisite for warming a garden house - the outer walls must be windproof.

To ensure that the walls are not blown out, it is enough to put some dense material under the outer cladding, be it thick paper, cardboard, roofing felt, roofing felt, glassine or plastic wrap.Facing from boards into a tongue or a quarter cannot be considered as windproof, even if it is tightly fitted, cracks will still appear, because the boards have defects, are subject to warping and shrinkage.

And so that rodents do not start in your garden house, which like to settle in any insulation, without disdaining glass wool, the work should be done carefully, without cracks. A ruberoid lining is a reliable protection from uninvited guests. After that, think about arranging a stove in a garden house with your own hands or installing a compact gas boiler.

Insulation of windows and doors

Do not forget to finally insulate the entrance door and windows through which the most heat is lost. The windows in the garden houses are mostly wooden, which require some preparation before the cold weather. Wood is an excellent material, but over time it warps, jars, it dries up, paint peels off. As a result, cracks appear, and cold penetrates through them.

A summer cottage with non-insulated wood windows can be heated for a long time, and it will still be cold. The house, in the end, will warm up, but if the power of the heater decreases, or if you do not put wood in the stove, it will instantly become cold again in it. And the reason for this is the drafts that penetrate from these cracks in the windows and take away heat. Therefore, the issue of thermal insulation of windows begins with a tight fit of the frames. Be sure to inspect the places where the windows meet the walls.

Check if it comes out from the gap between the frame and the glass, and if you notice a "leak", then just replace the glazing beads. It is also recommended to glue the windows in the autumn. You can follow grandmother's advice and do the old-fashioned way: with paper that is glued to the paste - a solution of flour and water. You can purchase duct tape from hardware stores, which works well as well.

If there are large gaps between the frame and the window sashes, it is better to pierce them with cotton wool before pasting. And in order to minimize window heat loss, it is recommended to install reinforced-plastic windows with two- or three-layer glazing, as well as use glass with energy spraying and putty all the gaps.

It is good if the garden house has a vestibule, in other words, the front door is separated from the living quarters by another door. In this case, there should be no strong drafts and cold bridges from the street. And yet, the front door to the cottage, regardless of whether there is a vestibule in front of it or not, is recommended to be sheathed with insulation. To insulate the door, place an insulating material between its walls, and glue the jambs and the joint of the door with insulation.

The simplest thermal insulation material is suitable, the one that is sold as a set of dermantine, foam rubber and decorative nails. The cost of such a set is not too high. Everything will cost you a couple of hundred rubles. But the insulated door will help the owners save more than one kilowatt of electricity on heating.

Insulation of doors

For maximum efficiency, doors should also be insulated, especially entrance and balcony doors. If there is a strong blowing from the door, then it is better to separate the platbands and fill the gap between the door frame and the walls with polyurethane foam. A special seal can be glued to the block along the perimeter of the door leaf. Now it is quite often found on sale. It is usually sold in rolls. For doors, it is best to use an adhesive-based rubber seal. Some of them provide for the possibility of fastening to nails. Silicone or foam rubber are not very suitable for entrance doors, since they are less durable and wear-resistant, in addition, they do not tolerate frost well.

You can also insulate the door leaf itself, if necessary. If the door is wooden and too thin or a simple metal single layer, it will give significant heat loss.You can insulate the door by attaching a crate to it, in the niches of which heat-insulating panels are placed. Also, the door can be sheathed with special materials, this will also increase the thermal protection of the door.

Roof insulation

Roof insulation is in many ways similar to wall insulation. For this, as a rule, the same materials and technologies are used, but there are also some nuances. The correct installation sequence is important here. Of course, a high-quality and properly installed roof is of paramount importance. A waterproofing vapor-permeable film must be laid, in addition, it has windproof properties. Then a layer of insulation is laid, followed by another vapor-tight membrane. There should also be a small space for ventilation, which helps to avoid excessive humidity in the room. After that, all this is covered with plywood, drywall or any other suitable material.

House warming process

Arrangement of the thermal insulation system of a country house includes insulation of floors, walls, ceilings, doorways and windows. Each of these activities has its own characteristics.

The sequence of these operations is not fundamentally important and is determined based on the individual characteristics of the house. For example, if the walls are insulated from the inside, then they are first insulated, and then they work with the floor and ceiling.

Working with wall surfaces

Do-it-yourself wall insulation is preferable to be performed outside, because at the same time, the inner space of the country house, which is often not spacious enough, does not undergo any changes. Before applying the thermal insulation coating directly, the surfaces are thoroughly cleaned of dust and dirt, treated with protective solutions against insects and rodents.

Also, layers of waterproofing and vapor barrier are pre-created. After completing these steps, the frame is mounted, the step between the slats of which is about 50 centimeters. The thickness of the frame structure itself should be 2-5 centimeters more than the layer of insulation to be laid in order to provide a ventilation gap.

The selected thermal insulation material is placed directly between the racks and covered with a film from the outside to protect it from external factors.

Special dowels are used to fix the insulation. After the installation of the thermal insulation layer is completed, the walls are covered with a facing material, for example, siding.

Floor

When performing the insulation of an already operated country house, the old floor covering is completely removed. It is imperative to do this in order to evenly distribute the heat-insulating material, regardless of whether the work is being done by builders or by their own hands.

Next, a structure is formed from longitudinal bars. It must be remembered that they will hold the finished floor, so strong materials should be preferred.

After laying the beams, a heat insulator is laid. It is preferable to use cellulose insulation, but you can also choose expanded polystyrene. The finished heat-insulating layer is sheathed with new boards, then the flooring is laid.

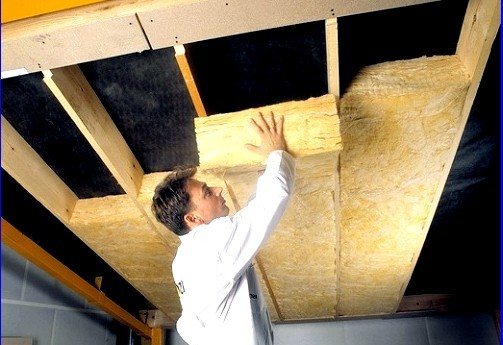

Thermal insulation of the roof and ceiling using mineral wool

In the absence of a properly insulated roofing structure, the insulation of a country house is practically useless. Indeed, according to the laws of physics, warm air tends to the top.

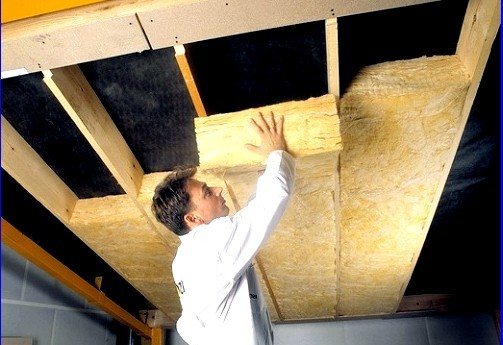

For roof or ceiling insulation, you can choose mineral wool. It is a lightweight material that does not create significant stress on structures. At the same time, it fills all cavities well, without letting heat out. When working with mineral wool, be sure to use protective goggles or a mask.

If the attic is not used for living, you can limit yourself to the thermal protection of the ceiling.Insulation plates are laid in the space between the ceiling beams from the attic side onto a pre-laid vapor barrier layer. The width of the mineral wool fragments should be slightly larger than the distance between the beams. The gaps formed after installation should be filled with polyurethane foam. Then a layer of waterproofing is attached to the beams using self-tapping screws.

When arranging an exploited attic space, the main efforts for thermal insulation are shifted to the insulation of the roof itself. The role of the frame in this case will be played by the bearing beams.

It is important to take into account that before laying mineral wool, it is necessary to lay a layer of waterproofing material, on top of which the insulation is installed.

As in the case of thermal insulation of the ceiling, all gaps left after laying the insulation must be sealed with foam. Then, using a stapler, a vapor barrier layer, for example, glassine, is attached to the mineral wool. For secure fixation, the entire structure is fixed with counter rails or a profile.

Insulation of door and window openings

Thermal insulation of doorways and windows largely depends on the characteristics of the doors and window structures used. If the front door is made independently, then the space between the outer and inner layers must be filled with insulation by analogy with wall insulation.

Also, an important point in thermal insulation of openings is to ensure tightness between the walls and directly door and window frames. For these purposes, it is recommended to use special sealants and fillers.

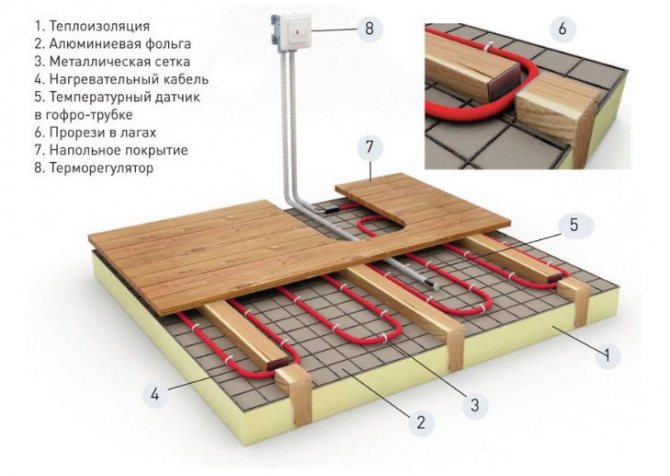

Warming of floors

Floor insulation is one of the most time consuming processes. First you need to dismantle the finished flooring Then, if the logs and the subfloor are in a suitable condition, then insulation is laid and the final floor is laid. One of the best and most modern methods is the underfloor heating system. But due to the rather high price and complexity of the installation, it is not always applicable for a country house. In addition, it significantly increases the load on the power grid, which is not always designed for such systems. Therefore, the floor, insulated in traditional ways, is more common in summer cottages.

Comprehensive insulation of the building will help keep warm. The elimination of freezing of the room, in turn, significantly increases its service life, and also helps to better preserve the interior decoration for a longer period. And furniture, appliances and other utensils will remain useful much longer. This will make your stay at your favorite summer cottage even more pleasant and comfortable.