Keeping your home warm is one of the top priorities for a comfortable and healthy life. To retain heat from below, a system of “warm floors” is used; to prevent heat from escaping through walls and windows, various plastic structures are used. But it is especially important to eliminate heat loss through the ceiling. And because about thirty percent of the heat goes through the top of the room (due to the convection effect), and because the lack of thermal insulation leads to the formation of condensation on it (due to the temperature difference on both sides of the ceiling) and an increase in humidity in the room, which means to the appearance of fungus and mold.

Polyfoam has zero vapor permeability. In addition, this material is easy to install and a fairly budget option for effective insulation.

Fastening of insulation to the ceiling can be carried out both from above (from the attic) and from below (in the room).

If for some reason it is impossible to insulate the ceiling from above, then for insulation from below the best option is to use the following non-bulk (expanded clay, sawdust) materials:

- polystyrene (expanded polystyrene). It is produced in the form of squares measuring 1 × 1 m, with a thickness of 2 to 10 cm. It is non-hygroscopic (does not damp), which means that the thermal insulation does not change with fluctuations in the level of humidity. It is easy to fix with glue to the rough base of the ceiling, therefore it is also used as an intermediate insulation for suspended frames;

- mineral wool (glass wool, basalt wool, ecowool and other varieties). Supplied in rolls (carpet) and bales (blocks). In the roll type, one side of the mineral wool can be covered with foil, which increases the effect of thermal insulation. Fastening to the ceiling is carried out using a wooden or metal frame made of profiles. Cheaper than polystyrene with the same good thermal insulation. More environmentally friendly, as mineral fibers do not emit harmful substances. Possesses high fire safety and retains all its properties at temperature extremes. It is not subject to decay and is not a breeding ground for insects;

- foamed polyethylene foam - foamed polyethylene glued to aluminum foil. Available in rolls 100 cm wide and 1 to 20 mm thick. Often, thin insulation is used in combination with mineral wool to increase the power of the thermal barrier and protect against carcinogens that can come from certain types of wool. It is convenient to fix it with glue and construction fungi-dowels;

- polyplex. It is obtained from expanded polystyrene by extrusion (forcing through special forms of polymer melt). It is produced in sheets with a size of 60 × 120 cm with a thickness of 1 to 20 cm. It has a high density, and therefore is often used both as insulation and as a rough base for ceiling putty. Can be fixed with dowel mushrooms or U-shaped holders.

Insulation from below: how to fix

To create a frame from transversely and longitudinally located profiles, cells are made, attaching them to the ceiling with nails, dowels or screws.

For any insulation, either special fasteners or a suspended frame will be needed. The easiest way is to fill the space between the suspended and main ceilings with a thermal insulator. In this way, it is convenient to fix the insulation in high rooms. For rooms with a small space, it is more convenient to use penoplex or polystyrene, the sheets of which are glued to the ceiling with ordinary tile glue, and then fastening with special construction fungi-dowels is performed for greater strength.

Considering the popularity of such insulation as mineral wool, in view of its durability, environmental friendliness, fire resistance and low prices, let us dwell on its ceiling installation in more detail.

Stages of work

Ceiling insulation scheme with mineral wool.

We use mineral wool in the form of slabs, wooden beams (you can use a metal frame) and drywall sheets.

- A layer of waterproofing, any insulating material (film, glass beads, etc.), is attached with a stapler to the rough base of the ceiling. Cloths of the film with a stele overlap a few centimeters.

- The assembly of the frame, wood or metal, is fixed with a puncher and dowels.

- Laying mineral wool: we glue the wool slabs to the ceiling using tile adhesive (provides quick adhesion of the ceiling and wool surface).

- On top of the insulation, we again lay the waterproofing material.

- We mount plasterboard ceiling sheathing using self-tapping screws.

Tools and materials other than cotton wool:

- knife, hacksaw, hammer;

- self-tapping screws, screws;

- grinder, electric drill, screwdriver;

- construction stapler (fix the film to the ceiling);

- waterproofing film, wooden beams or metal profiles, drywall, polyurethane foam.

For any owner who knows how to hold tools in his hands, insulating the ceiling in his house on his own is quite a feasible job. And realize your tastes, and save the budget!

Inhabitants of private houses are often very cold in winter. Indeed, through windows and doorways, cracks in the floor, as well as walls, heat goes outside. To solve this problem, mineral wool helps well for insulating the ceiling.

Below in the article, a video of the ceiling insulation with mineral wool with your own hands is published, as well as the main nuances of installing this building material.

Tools and materials used in the work

It:

- insulation;

- insulating material;

- waterproofing;

- board (30x150 mm);

- nails;

- rail (10x20 mm);

- mounting foam;

- jigsaw and hacksaw;

- hammer and knife.

Most of the insulation materials for the ceiling are exactly the same, they are based on one function. They differ only in the method of installation and the condition of use in a particular case. Therefore, which heat insulator to choose depends only on you and your preferences. This is all that can be theoretically told about the materials and insulation of the ceiling.

You might be interested in: there are curtains for the kitchen here

What is the best mineral wool for the ceiling

When choosing, pay attention to the thickness of mineral wool for ceiling insulation. For soundproofing the ceiling in the apartment, fire-resistant mineral wool 5 cm thick is nailed to the top.

The ceilings of a cottage or a private house are covered with at least 15 cm thick mineral wool. An important indicator is the density of the mineral wool. The higher it is, the greater the load the building material can withstand. Such a density is considered optimal - 80 kg / cu. m.

On sale there is mineral wool in tiles and in rolls. Slabs are bought for internal insulation, because they are made according to standard sizes and it is more convenient to cover the surface of the ceiling with them. When insulating from the side of the attic, mineral roll wool is used.

Mineral foil wool is also sold on the construction market. It is more expensive than usual. However, when attaching mineral wool to the ceiling, they do not additionally buy a waterproofing building material - foil-clad polyethylene foam or a dense polyethylene film.

Sheathing of ceilings with mineral wool is carried out in the attic or indoors. More on this below in the article.

Mineral wool

In addition to the decorative role, the ceiling in the room also performs other important functions - soundproof and heat-shielding. Mineral wool is often used by real estate owners when they solve the problem with floor insulation. This material consists of fibers produced from textiles.

Mineral wool is sold in blocks or in rolls.The highest degree of thermal insulation is possessed by products made in the form of a mat. It differs not only in the best performance, it is easy to work with it when the mineral wool is attached to the ceiling.

Thanks to the use of this material, it is possible not only to insulate the room, but also to protect it from noise coming from the outside, since it is an excellent sound insulator.

Many home craftsmen are interested in how and how to fix mineral wool to the ceiling. Dowels with wide heads are used for installation. In addition, self-tapping screws and self-adhesive tapes are used for a more durable fixation of the insulation.

Instructions on how to fix mineral wool on the ceiling will help you do this job correctly:

- Measurements are taken from the ceiling surface on which the installation will be carried out.

- Insulation plates are made the same and corresponding to the measurement results.

- Holes are drilled in the ceiling for dowels, it is better that they are plastic. With their help, metal profiles are attached to the ceiling base.

- Mineral insulation is placed on the crate.

- After the mineral wool is laid, the entire structure is fixed with dowels.

- Sheets are laid on top and fixed well. This is done using wooden slats and nails that look like mushrooms. They received this name due to the presence of a wide cap on top.

- In the process of fixing the mineral wool to the ceiling, there are cracks and joints, which are filled with polyurethane foam.

The process of thermal insulation using mineral wool has a number of advantages:

- this insulation is environmentally friendly;

- hypoallergenic material;

- has a long service life;

- does not deform;

- the fire safety of the material expands the range of its possible applications;

- can be installed in baths and saunas;

- has a high level of vapor permeability.

An important point in the process of how to attach mineral wool to the ceiling is that the material must be placed tightly, but at the same time it must not deform, otherwise it loses its original qualities. To extend the period of operation, it is advisable to treat the surface with an antifungal compound after the installation is completed.

There is an adhesive option in which the frame or crate is not assembled. Plates are glued to the base treated with a primer and fixed with dowels. Before deciding how to glue the mineral wool to the ceiling, you need to choose the right glue.

Polymer-cement compositions should be used, which make it possible to fix mineral insulation most effectively. This kind of glue is sold as a dry mix in large bags and diluted in a certain amount of water. These compositions have high vapor permeability.

How to insulate the ceiling in a private house with mineral wool

Before installing the insulation, they first decide how to fix the mineral wool on the ceiling - outside (from the attic), inside (in the room), or both (combined method). External thermal insulation of the ceiling of a cottage or a private house is considered a more convenient, simple and economical installation method with such a building material, but the second method is not always used.

Since a false ceiling is installed in the room with internal insulation of the ceiling with fire-resistant mineral wool, the second method is not suitable for low private houses. Only if the height of the room is more than 2.5 m, then ceiling insulation with this building material is considered justified.

When using a combined installation, mineral wool is laid both from the attic and from the room side. More often, such installation work is carried out in a sauna, bathhouse and other places where it is necessary to ensure a high constant temperature for a long time.

Preparation for the installation of mineral wool on the ceiling

In order to properly insulate the ceiling with mineral wool, in preparation for installation, perform the following actions:

- calculate the amount of insulation (how many building materials are needed to install ceiling steam and waterproofing);

- prepare tools - a stapler, tape measure, knife, adhesive tape, several wooden slats, metal guide profiles and fasteners;

- prepare personal protective equipment - glasses, clothing, respirator and gloves.

The insulation is unpacked only before installation. After the completion of the work, the room is cleaned with a vacuum cleaner, and then they take a warm shower.

Thickness of mineral wool for ceiling insulation

When choosing the thickness of the fire-resistant mineral wool, the climate in which the private house is located is taken into account. The quality of the installation work is directly related to the thickness of such a heater and the value of the thermal conductivity coefficient. Mineral wool mats, which have a low density, have less insulation thickness than tiles.

The thickness of mineral wool mats for thermal insulation of private households in northern latitudes is 206 mm, and in the middle lane - 163 mm. As a result, dense mineral wool has good thermal conductivity and is a fire-resistant building material.

The outer walls of private households or cottages in the middle lane are covered with a layer of mineral insulation wool, the thickness of which is 120-140 mm. Moreover, the standard thickness of the insulation is a multiple of 50 mm. Mineral wool 80 mm thick cover the ceilings in IZHS houses.

How to attach insulation to the ceiling

When insulating a ceiling covering with mineral wool in a cottage or in a private house, the following tips from professionals are followed:

- the crate of several metal guide profiles is fixed with steel screws, they firmly fix the mineral wool on the ceiling;

- during installation, mineral heat-insulating wool is not specially tamped and compressed with a press, such actions significantly reduce the thermal insulation of the building material;

- if the ceiling lathing is thinner than mineral wool, then in this case several wooden beams are stuffed onto the main boards.

Insulation of the ceiling from above

The process itself, how to fix the insulation on the ceiling, involves the use of different methods.

Today, two types of them are known:

- top;

- bottom.

The upper insulation is performed from the side of the attic of the building, which is important for private households, in the following sequence:

- During the first stage, the beams are hemmed.

- Install insulation.

- Insulation is laid.

- Finally, cladding is done using boards in order to create conditions for free movement in the attic.

The advantage of this method is that you do not need to think about how to attach the insulation to the ceiling if you use bulk material, for example, expanded clay or sawdust. It is important that in the end there is no empty space left.

Regardless of the decision taken on how to fix the insulation to the ceiling, the following tools and materials will be required to carry out this work:

- hacksaw or knife;

- screws and nails;

- Bulgarian;

- electric drill;

- a hammer;

- construction stapler;

- polyurethane foam;

- metal profiles;

- screwdriver;

- dowels and screws.

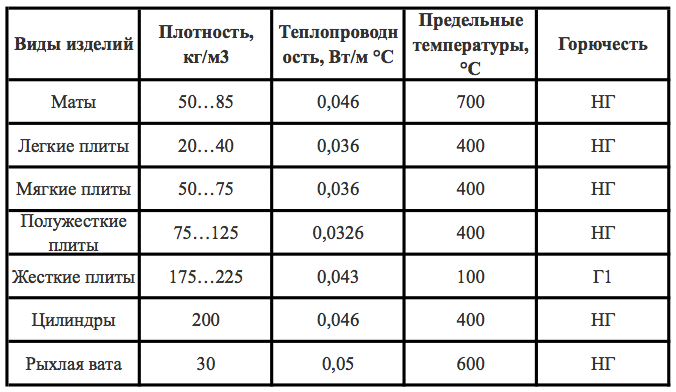

The choice of mineral wool by technical indicators

Insulating the ceiling in a private house with mineral wool means choosing the right material. The answer to the question of which mineral wool is better, experts consider on the basis of characteristics.

Insulation has two classifications:

- Mats - low strength indicators. Sold in rolls for easy transport.

- Plates - increased strength, two types - rigid and semi-rigid.

- Cylinders are a special material for pipeline insulation.

According to the raw materials used for the manufacture: basalt wool, glass, slag.

It is basalt fiber that has become widespread.Stone wool (the second name for basalt slabs) is highly durable and is used to insulate ceilings and walls subject to intense loads, incl. mechanical.

The material is produced from crushed and molten basalt as a result of which the material has a fibrous structure. After that, the fibers are pressed and heated at high temperatures. Produces basalt wool, including in the form of slabs.

Characteristics and manufacturers

There are the following types of mineral wool:

- Glass wool is made from melted glass and sand. Borax, limestone, soda and dolomite are used as fillers.

- Slag wool is produced from blast furnace slag. Its structure is fine-fibred. However, it is not suitable for use in residential premises due to the content of harmful substances.

- Basalt wool is made from molten rock. Clay, limestone and dolomite act as a filler. It is the densest, strongest, most durable and non-combustible type of mineral wool.

Mineral wool specifications:

- strength depends on the brand and ranges from 0.08 to 0.6 kg per square centimeter;

- density ranges from 35 to 100 kg per cubic meter;

- minimal shrinkage;

- thermal conductivity from 0.036 to 0.06 W / m ° C;

Important! When used in humid conditions, thermal conductivity increases by 50 percent.

- water absorption 6-30 percent with full immersion in water (moisture content of dry cotton wool 1%);

- frost resistance differs from manufacturer to manufacturer;

- vapor permeability reaches 1;

- sound insulation coefficient - from 0.7 to 0.9;

- fire resistance - the material belongs to the class NG (non-combustible);

- mineral wool is not toxic and does not harm health;

- maximum service life up to 50 years;

- the price per square meter of material is at least $ 2.

Famous manufacturers of mineral wool include such brands as Isover (Isover), Rockwool, Ursa (Ursa), Beltel, Knauf, Paroc and IZOVOL.

Pros and cons of warming the ceiling with expanded clay in a wooden private house

Advantageous indicators and choice of board thickness

Mineral wool has the following advantages:

- a light weight;

- elasticity;

- fire resistance;

- low price;

- long service life.

The thickness of the mineral wool is an important parameter when choosing a material. This indicator depends on the ceiling coverage. It also takes into account which method will be chosen to insulate the ceiling with mineral wool. So, with concrete floors, cotton wool is chosen with a thickness of at least 10 cm.In the presence of a heated attic, an insulation with a thickness of 8 cm is used.A pitched roof type involves the installation of a 30 cm thick mineral wool.

What materials are used to insulate ceilings

You can insulate the ceilings in a wooden house both from the inside and outside, in the attic. Sometimes the ceiling is insulated in a complex way - from the outside and from the inside. Materials for ceiling insulation are selected based on their own financial capabilities and depending on the method of insulation. So, if the ceiling is insulated from the outside, it is very convenient to use the following types of insulation:

- Bulk - expanded clay, shavings.

- Slabs - polystyrene.

- Porous-fibrous - mineral wool.

- Sprayed - polyurethane foam.

If a wooden house was built quite recently, finishing work is still being carried out in it, then this is the most suitable time to insulate a wooden ceiling with mineral wool, after which you can immediately start finishing the ceiling. A frame is attached to the wooden ceiling, in the voids of which sheets of mineral wool are laid. The frame also serves as the basis to which the ceiling finish is attached - lining, gyiscardboard, fiberboard, etc. Since the frame carries a certain load, we recommend using an edged board 40x150x6000 during installation.

One of the main conditions for high-quality insulation of the ceiling, regardless of the material used, is laying a reliable vapor barrier. Glassine is most often used as a vapor barrier material. The insulating material is laid between the joists, fixed with a stapler. The overlap between the sheets should be at least 10 centimeters.

Types of fasteners and technology for fastening mineral wool indoors

Insulation laying indoors, as a rule, is carried out in an apartment. Fastening of mineral wool is carried out in several stages:

- Erection of the frame. To do this, it is necessary to install a metal lathing for the false ceiling. The profile of the metal batten has standard parameters. For a wooden frame, boards of 30 × 100 mm or 40 × 200 mm are used, based on the weight of the boards. That is, the heavier they are, the more massive the crate will be. The slats must be fixed with dowels with suspensions, with a step of 55-60 cm. This distance is optimal when laying mineral wool in slabs.

- Installation of waterproofing material. The film is cut into strips of 65-70 cm, i.e. slightly larger than the width of the spacing between the slats. For fastening to a wooden frame, nails are used, for a metal one - self-tapping screws.

- The insulation is laid in two ways - using a construction stapler or on a specialized paste. Parallel to this, a vapor barrier is installed as a top layer.

The result of quality work is a consistently strong "cake" of three layers without gaps between the mineral slabs. Plasterboard is placed on the lower profile, which covers the thermal insulation. After that, you can install lighting devices and carry out decoration, according to the project.