Refractory tiles are a facing material with high strength and heat resistance. It is used to decorate hearths, fireplaces, stoves, and walls and floors of buildings adjacent to them. Ordinary tiles cannot be used for such objects. It will crack quickly, lose color and texture, and you can burn yourself when touched. Heat-resistant cladding is made according to a special recipe and technology. Manufacturers use different raw materials in production, the result is decorative tiles with parameters that differ from each other.

The main characteristics of the refractory lining:

- Environmental friendliness. When heated, any materials emit substances into the space, since heat-resistant cladding is used in residential premises, it should not contain toxic and hazardous substances.

- Heat resistance. To obtain this quality, slabs go through one or two firing. This is reflected in the marking with a flame tongue symbol and a number. The result is a material capable of heating at least +1000 degrees C.

- Thermal conductivity. Plates must transmit heat as they are used on heating appliances for space heating.

- Water absorption. This parameter cannot be more than 3%. In the marking, it is indicated by the letter E, and a number that shows the specific values for this modification.

- Strength and rigidity. The thickness of heat-resistant tiles must be at least 8 mm, these dimensions provide the necessary strength characteristics and stop the risk of deformation.

- Expansion at temperatures. This figure should be in the range from 7 to 8%.

- Resistance to mechanical stress. Only fine-pored materials have this quality. The smaller the pores, the stronger the veneer. In the marking, this characteristic is denoted by the letters PEI and Roman numerals up to V, the higher they are, the greater mechanical stress the heat-resistant ceramic plate will withstand.

Important! In addition to technical characteristics, the cladding should have an aesthetic appearance, keep it for a long time not only when heated, but also when temperature drops, for example, in a bath.

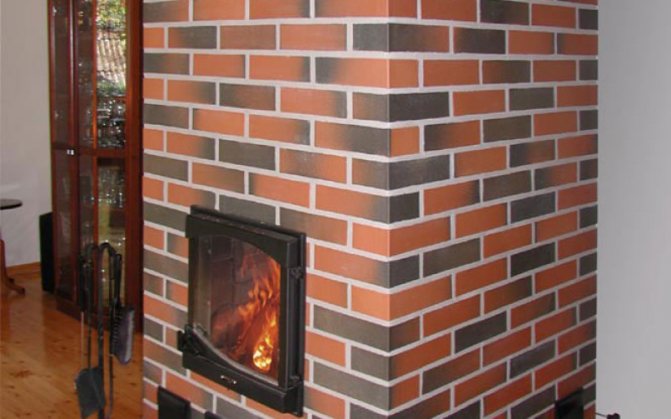

Heat-resistant tiles are stable in contact with open fire

Positive features of clinker tiles

Clinker products have many positive aspects:

- Resistance to loads, abrasion, all kinds of damage. It is this advantage of brick that makes it possible to make a choice in its favor for the most impracticable tasks, for example, paving sidewalks and various purposes of sites, finishing stairs, etc.

- Resistance to aggression of substances of chemical origin;

- Minimal moisture absorption;

- Resistance to frosty weather, which is an important position for our climate;

- Maintaining the brightness of the color gamut during the entire period of use;

- Large assortment of colors and textures;

- Ease of restoration work and maintenance;

- Also, an important point, economy is attached to all the benefits;

- Clinker differs from ceramics in structure - it is fine-grained, high data in terms of resistance to mechanical damage, as well as low moisture absorption. In addition, the clinker material has high performance in terms of individuality and uniqueness of charm.

https://youtu.be/upGHXJsBcuA

Features of the choice of materials

The choice of refractory tiles for a stove or fireplace is carried out according to several criteria:

- Cost. If the price is high, it is not worth buying the material less than necessary or exactly in the calculation, there will be mistakes during installation.

- Strength. The larger it is, the higher the guarantee of reliability and durability.

- Heat capacity. It is important that the facing layer does not retain heat from the heater and distributes it evenly.

- Porosity. Low porosity guarantees moisture resistance and mechanical strength.

- Thickness. This size cannot be less than 8 millimeters.

- Styling and care. The cladding should fit well and be easy to maintain.

Note! When choosing refractory tiles for the wall behind the stove, hearth or fireplace, you can pay attention to modifications with lower fire-resistant parameters. By design, they can repeat the design of the hearth, harmonize with it or contrast.

Chamotte finish in package

How to choose material

Not every tile is suitable for decoration, and it is not always a matter of quality.

- Heat resistance - denoted by the letter "T". The tiles must be fire resistant.

- Preferred thickness for a fireplace - 6–8 mm. It is impossible to thinner, because here the material undergoes constant heating, and the thin tile will quickly collapse. The best tiles for cladding are square tiles, with a size of 120 * 120 mm. With large dimensions and maintaining the same thickness, the rigidity and strength of the masonry decreases. And with increasing thickness, there are problems with fastening: the glue has a limited ability to hold weight.

- Tile color should vary within small limits, unless, of course, a special decorative technique is used.

- It is very important for tiles dimensional accuracy... It's not even about the aesthetic side of the issue: with different dimensions, it will not be possible to lay the tiles tightly. Therefore, the clinker should be checked: fold 2 tiles together "facing" each other, and then with the wrong side. There should be no gaps between the surfaces. Defects on the front side do not allow you to form a flat surface, on the wrong side - to lay tiles. According to this parameter, clinker is divided into 2 classes - "A" and "B". The first one promises more accurate measurements.

- Cracks and chips unambiguously indicate the poor quality of the product. Moreover, the cracks on the seamy side are no less dangerous - this is a guarantee that the tile will burst under the influence of temperature in the near future.

- For cladding you need to choose unglazed clinker... The enamel layer noticeably affects the coefficient of thermal expansion, and it is not resistant to temperature extremes.

This video will tell you about the choice of adhesive for fireplace clinker tiles:

Styling features

In principle, the installation of the facing layer on heating devices differs little from laying ordinary tiles, but there are some nuances:

- the overall structure can be reinforced with a metal braid with 15x15 cm cells or aluminum corners, these devices are placed between the stove and the tile, they are fixed with nails or self-tapping screws;

- the reinforcing layer is covered with a solution of sand, clay and cement, the mark of which should not be less than M400, experts also recommend adding glue with polymer additives based on aluminate cement to it, the layer thickness should not be more than 1.5 cm, otherwise there is cracking risks;

- if metal elements are used for rigidity, the distance between them and the cladding itself must be at least 1 centimeter;

- the tile is laid through the usual stopper-limiters, when it is all installed, they are taken out;

- the seams between the elements are closed with grout.

Attention! For installation, you need to choose an adhesive with heat-resistant qualities. These can be materials based on alkaline metal silicates. Other species will not be able to withstand the upcoming operating conditions.

Laying the cladding on the oven

Installation

In principle, the laying of clinker or other tiles - terracotta, majolica, is no different. The hearth is a fairly simple design, although here too you have to tinker a lot to achieve aesthetics: the material has to be cut, but it is desirable that whole tiles are located in a conspicuous place.

Clinker is attached to glue, and attention should be paid to its choice.

- Firstly, the composition must withstand the weight of the cladding so that the tiles do not slide down under their own weight during hardening.

- Secondly, it must be heat-resistant.

Brick is a sufficient base for clinker, but it needs plastering: the tile is demanding on the curvature of the surface and will not tolerate height differences of more than 2 mm per square meter. m. If a decorative hearth is faced, then the possibility of finishing depends on the strength characteristics of the structure.

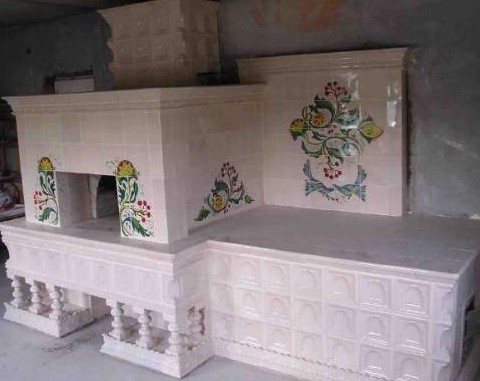

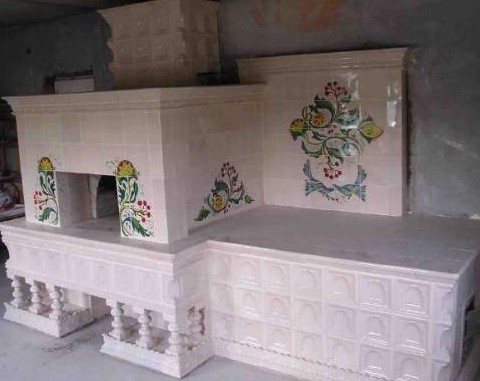

Clinker tiles for the fireplace (photo)

What is needed

The tools and materials for clinker cladding are quite traditional.

- Tiles - with a margin of 10-15%. You will have to cut the material.

- Tile cutter - this tool usually does the job. If not, you can use a grinder with a diamond blade.

- Electric drill with mixer attachment or construction mixer.

- Plaster mixes - ready-made and made on the basis of clay and cement grade not lower than M400.

- Heat-resistant adhesive capable of withstanding heating up to 500 C.

- Mesh-chain-link - with a mesh size of 5 * 5 cm, self-tapping screws for fastening.

- Mounting crosses.

- Spatulas - smooth, serrated for glue application, and rubber for grouting. Rubber hammer.

- Plumb line and level to check the horizontal seams.

- Metal brush and hard sponge.

Preparation of the base

Whether it's a new fireplace or a renovation of an old one, the surface must be prepared for the job.

- The body of the hearth is cleaned with a metal brush from the old plaster or the seams between the bricks are cleaned by at least 10 mm. Remains of clay and dust are removed with a damp sponge.

- The body is primed. The mesh-netting is fixed on the surface with screws. Self-tapping screws must fit into the body of the brick; they cannot be fastened to the seams. Reinforcement is desirable, since clinker is not the lightest material, and the plaster layer may simply not withstand its weight.

- Before plastering, the surface is wetted. The plaster is applied in a sufficiently thick layer so that the mesh is recessed and carefully leveled. The plane is verified with a plumb line and level. After drying, the screws are removed - this is a temporary fastening. The holes from them are sealed with the same primer.

- After leveling the fireplace, you need to heat it to make sure the quality of the work. Then you can start cladding.

We will tell you about the options for lining stoves with clinker tiles with our own hands below.

Examples of clinker fireplace cladding will be described in this video:

Cladding technologies

The cladding begins with a marking. It is important to ensure that the whole tiles are in the center of the composition, and the cut ones are closer to the corner. Corner tiles will help a lot here, but they are not present in all collections.

- If possible, you need to lay out on dry, at least several rows, in order to correctly calculate the number of whole and cut tiles. Then markings are made with horizontal lines, taking into account the thickness of the tile seam.

- Prepare the glue according to the instructions. The composition loses its properties after 20-30 minutes, so it needs to be cooked in small portions, based on the amount of 1 sq. M. m.

- Starts laying from bottom to top horizontally. Diagonal is only allowed when using square tiles.

- The first row is the most difficult. If the joint between the hearth and the floor overlaps the plinth, then a thin metal rail is fixed at this level. It will serve as a support for the first row, and at the same time will not allow you to break the horizontal. After drying, the strip is removed and the plinth is fixed. If there is no plinth, the profile is fixed at a level equal to the width of the clinker, taking into account the joint gap. In this case, laying starts from the second row. The first row is laid after the entire hearth has been laid out, the glue has frozen, and the rail is removed. If necessary, tiles can be cut to width to achieve the perfect finish.

- The glue is applied with a smooth trowel, then leveled with a notched trowel. The thickness of the layer depends on the thickness of the tile, usually 6–8 mm.

- The clinker is applied to the site, pressed down, tapped with a hammer to expel air.Mounting crosses are installed between the tiles. The thickness of the seam is at least 10–12 mm, since it must take into account thermal deformation. The laying in each row must be started from the corner, but with whole tiles, and then the trimmed ones must be fixed.

- Every 2 rows it is necessary to check the horizontal level of the masonry.

- The clinker is placed in belts in 3-4 rows. The next fragment is laid after sufficient setting of the previous one.

- Grouting is carried out after the glue has dried: depending on the composition, this is 1-3 days. Semi-dry mixtures or even an aqueous solution of glue are used. If the clinker is smooth, the mixture is applied with a rubber spatula; if the decorative is embossed, it is better to use a special gun.

- The grout in the seams is leveled with a damp sponge, and the excess is removed with it.

Trade marks

- BayKer. Products of an Italian company. It is produced in a variety of types, has excellent user reviews, effective design, reliable and durable. Cost - from 2 thousand rubles per package.

- Terracotta. Russian product. The manufacturer specializes in the production of tiles and all materials for their installation: glue, mastic and others. Various models. Price - available: from 500 rubles per package.

- Alliance tiles. Russian manufacturer of refractory cladding, porcelain stoneware, clinker. The products are characterized by spectacular design and decent performance parameters. Cost - from 1 thousand rubles.

- Aparici Agate. The Spanish manufacturer offers plain, fireproof and mosaic tiles. The building material is characterized by exceptional performance and author's design. Semi-precious minerals are used in the decoration. Price - from 5 thousand rubles per package.

- Dado Ceramica. Mosaic and standard cladding design with emphasized style and laconicism. Cool tones and urban flair are characteristic of the Italian material. Price - 1 thousand rubles per package.

- Polycor. The Russian manufacturer specializes in refractories. The production has ancient traditions, the workshop was opened in 1894. High quality products with traditional designs. The choice is quite narrow, the cost is from 1000 rubles.

- Mosplitka. The metropolitan enterprise offers a large selection of tiles for residential and commercial premises. Good value for money. A network of retail outlets throughout the Russian Federation, an interesting offer of "own design", regular promotions, flexible prices - from 1,000 rubles.

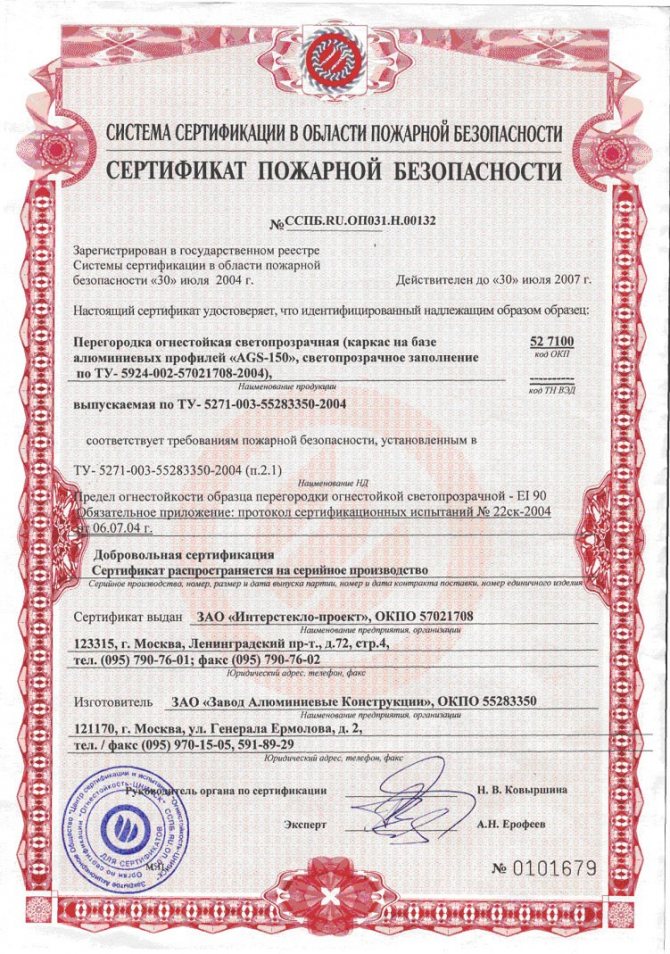

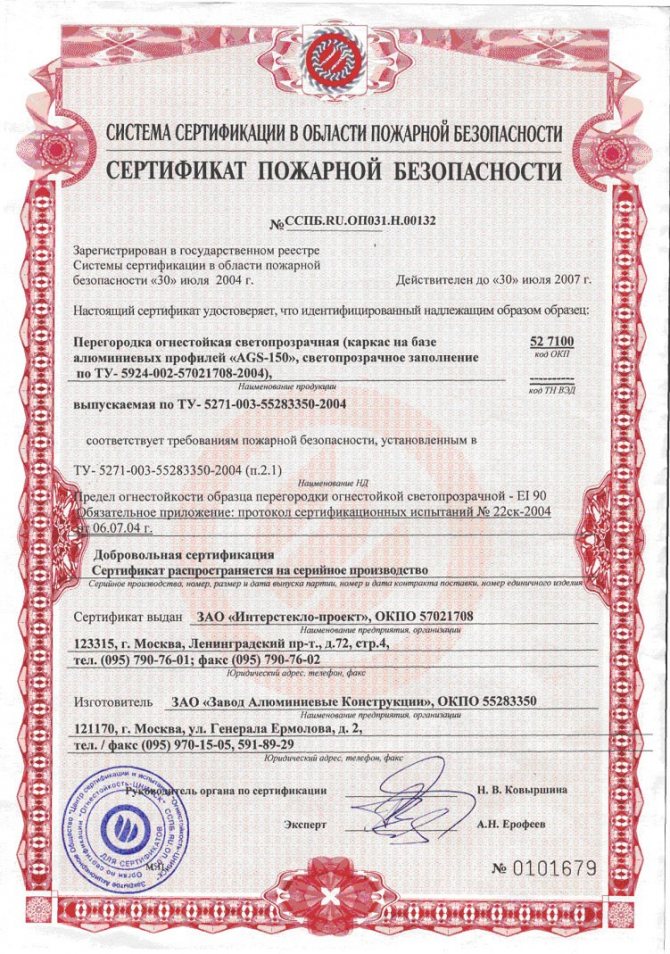

Important! The refractory material is accompanied by a certificate of conformity, which specifies the exact parameters. It is issued to the manufacturer based on the results of tests in a specialized laboratory.

Fire safety certificate

How the stove is lined with refractory tiles, see this video:

Cladding tile classification

Fireplace tiles, depending on their performance and other features, are divided into the following varieties:

| Cladding tiles | Properties and features |

| Clinker

| The tiles are made from natural materials, namely clay. Choosing a tile without applying glaze, you can get the most natural appearance and structure. Such a product performs well in rooms with high humidity and has a water absorption coefficient of less than two percent. Over time, the surface and the tile itself does not wear out, does not darken and retains its original appearance and all the characteristics assigned to it. Such material is suitable for finishing works of both stoves and fireplaces, and walls of buildings. |

| Terracotta

| The product is based on clay, which tolerates high temperatures and their drops well. The main advantages of terracotta products include the ability to choose almost any shade, structure (tiles can be coated or not coated with special glaze), has high strength and a smooth non-porous structure, which allows easy maintenance, adheres well and reliably to any surface. |

| Tiles

| They have a fairly high cost and have impeccable performance. This allows them to tolerate regular exposure to high temperatures well.The tiles on the reverse side of the surface have small sides, which allow it to be securely fixed and adhered to any surface. The top layer is presented in the form of glaze, each product is pre-fired. |

| Majolica

| Several times surpasses terracotta products in their properties and characteristics. The surface of each element has a small and durable layer, which over time remains integral, which prevents the tiles from cracking and chipping in various places. However, despite all the advantages, such material is not recommended for cladding sections of fireplace and stove surfaces in areas of strong heating. |

Important: in addition to the four main types of tiles indicated in the table, there are others that can also be used for facing surfaces. However, in terms of their characteristics, they are significantly inferior to the main ones. An additional classification can include: tiles, fireclay, porcelain stoneware, marble and artificial stone.

Fireplace tiles, ideal for all conditions of use. Despite the fact that the price for many varieties is quite high, it pays off due to a long period of operation, which can reach about 50 years.

Let's summarize

Fireplace tiles are more expensive than conventional tiles. But the market in this segment is fiercely competitive, so you can find solid and inexpensive modifications. To further reduce costs, it is advisable to purchase it from chain construction retailers: Leroy Merlin, Your House and similar retail outlets. Another option is to buy directly from the manufacturer, in which case you will avoid trade margins. But for stoves, fireplaces and hearths, ordinary materials cannot be used, otherwise there will be regular restoration of the facing layer and additional costs.

Selection recommendations

Clinker tiles for facing fireplaces and stoves are selected in accordance with several parameters:

- Impact resistance;

- Moisture resistance;

- Heat resistance;

- Product design;

- Thickness.

By the way, it will be said that the last of the characteristics has its limitations. It is advisable to select a material with a thickness of 6 mm. For the classic execution of facing material, this parameter is usually taken from the range of 7-8 mm and above, but not more than 12 mm. But for clinker, due to its low thermal conductivity, it is the 6 mm option that is recommended. The manufacturer and the price also play a role, but these selection criteria are not key, but rather auxiliary.

Until recently, the leaders in the market were Ruben and ABC brands. The cost of production, respectively, is equal to 1,700 and 2,800 rubles / sq. m. However, not so long ago materials of this kind from Russian manufacturers began to be introduced. In this case, the cost of tiles will be 2-3 times lower.

Customer Reviews

Wear-resistant clinker tiles for stoves or fireplaces are in good standing among users. This is primarily due to the excellent characteristics of this material. But in the case of lining the furnace structure, a long service life of the clinker cannot be guaranteed due to the coefficient of thermal expansion.

If it is planned to refine the fireplace, then this option is more popular today than others, which is greatly facilitated by a wide selection of shades and textures, in particular, you can choose an option that looks very similar to brick. Considering that the fireplace does not warm up as much as the heating stove, the tiles will last for a long time.

Composition of refractory tiles for stoves and fireplaces

It has already been mentioned that heat-resistant tiles are made from special clay. She, in turn, consists of special minerals in certain proportions. It is known that layers of its various types occur almost everywhere at one or another ground level. This rock is composed of aluminosilicates.And the color will directly depend on its chemical components:

- sodium;

- magnesium;

- kaolin;

- metal oxides and others.

At the same time, it is impossible to say exactly which components provide fire resistance. However, it is they who, when fired at high temperatures, give the materials strength. The key quality of such tiles is the absence of melting and the release of toxic substances.

Properties of facing materials for stoves and fireplaces

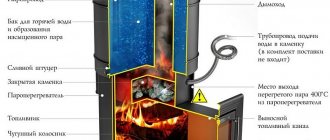

Refractory tiles are a quality material that can withstand high temperature loads. It is made on the basis of a special clay that is resistant to them. The production technology is also special: heat-resistant tiles are hardened under maximum limiting conditions. At the same time, the temperature can reach 1500 degrees. However, it is precisely this method of its production that guarantees high-quality operation as a facing material for special objects.

Fireplace tiles and other fireproofing equipment have their own varieties. But in terms of functionality, they are all the same. Their main task is to protect the furnace from temperature extremes and counteract its destruction.

Such materials are used during the final finishing of structures. Any refractory tile is durable and durable. It includes the following components:

- special clay;

- water;

- additives;

- finishing glaze with pigment.

Tile marking (designations)

The labeling (marking on the tile) on the packaging will help you to tell which tiles to use for facing the ovens. Depending on the type of tile, the following can be used:

- Letter "T" - denotes heat resistance.

- The numbers 1 and 2 against the background of the flame indicate the number of burnings. The higher the better.

- Letter "E" and number - water absorption is marked. The higher the number, the more moisture the surface can absorb. For a furnace, the indicator should not exceed 3%. For comparison, the water absorption of granite is 0.5%.

- The designations "A" or "B" on the packaging or the inside of the clinker tiles indicate the technology of their manufacture. Option "A" is more technological and has clear dimensions.

- The PEI index in grades from I to V will indicate the wear resistance of the tile. Any one can be used for the oven.

- The EN 122 standard, ranging from A to D, denotes the product's resistance to chemical attack.

Tile cost

The price of facing tiles and the reputation of the manufacturer are far from the last argument when choosing. Masters advise not to save on purchases, because the constant replacement of cheap tiles will ultimately turn out to be more expensive. The cost of tiles by type is shown in the table.

Based on this, it is easy to decide which tiles are needed for facing the stoves. But do not forget that the chosen tile should correspond to the general style of the interior of the room.

Choice of stove tiles in terms of design styles

It is not always rewarding to recommend this or that ceramics. Ultimately, personal tastes determine everything. But there are certain design guidelines to look at when choosing a tile.

Approximate matching of interior styles and tiles:

- in stove classics, tiled tiles and majolica are more often used;

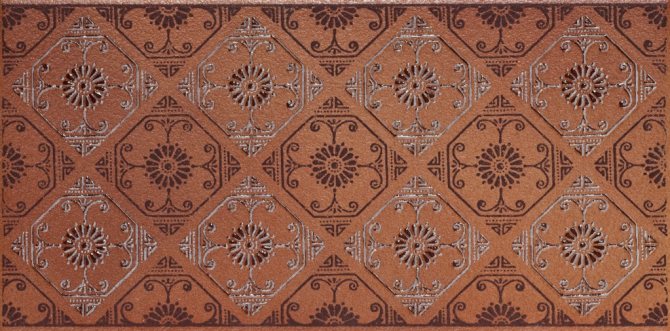

- stylistics referring to medieval motives, hints at a preference for ornamental designs; characteristic patterns can be achieved using thematic collections that are found in many manufacturers; here you can recommend using porcelain stoneware - this is the most diverse type of facing materials after tile;

- modern styles dictate the need to avoid complex patterns; such tiles for lining stoves should be stylish, but discreet; again, we recommend ceramic granite - a large number of imitations (wood, metal, stone) allows you not to deny your imagination;

- country style goes well with terracotta, clinker and artificial stone.