Wet insulation of facades using external thermal insulation, on top of which facing materials are applied in the form of liquid mixtures, is the most common way to improve the thermal performance of a house. And like any popular technology, wet facade insulation is often performed with many obvious or not so obvious mistakes. Let's describe the most common ones.

Errors in wet insulation of facades and poor attention to problem areas on the outer walls of buildings can nullify the dignity of the bonded thermal insulation system. Therefore, having decided to insulate the external walls with a wet method, you need to try to avoid mistakes in the choice of components, as well as avoid errors in the installation of thermal insulation and other structural details.

Wrong choice of insulation thickness

The thickness of the insulation for wet insulation of facades should be determined by the heat engineering calculation. It is important that the heat transfer resistance (R coefficient) of the outer wall is not lower than the current standards. The minimum values for 1 temperature zone of Ukraine R = 3.3 m2K / W, for zone 2 - R = 2.8 m2K / W.

On average, depending on the type and thickness of the wall material, the thickness of the insulation for external wall insulation is 10-15 cm, and sometimes 20 cm. Such a thickness of the insulation provides a displacement of the "dew point" (the section of the structure, the temperature of which is equal to the temperature of condensation of water vapor ) from the wall to the thermal insulation layer. As a result, the wall will be reliably protected from moisture and frost penetration. The use of a layer of thermal insulation of insufficient thickness will not provide effective thermal protection and will increase the cost of heating the house. In addition, this will negatively affect the structural performance of the wall over time.

And yet you need to understand that an unnecessarily thick layer of thermal insulation (above 20 cm) can worsen the appearance of the house. With such a layer of insulation, the windows will be recessed into the facade, and less light will get into them.

Selection of materials without taking into account the requirements of vapor permeability

For wet thermal insulation of facades, one of two popular heaters is usually used - foam or mineral wool. At the same time, the foam almost does not allow air and water vapor to pass through, while mineral wool, on the contrary, allows them to pass freely.

The vapor permeability of the layers of the facade insulation system should increase from the inside out, and the facade with mineral wool is equipped so that it is possible to drain condensate from the insulation. If the free circulation of steam through the mineral wool is not guaranteed, the insulation will be filled with moisture and lose its heat-shielding properties, and the wall will begin to freeze and mold and mildew will form on it.

First of all, this concerns the choice of finishing paints and plasters. In systems based on foam, you can choose almost any type of exterior finish, but when using mineral wool, only vapor-permeable silicate, silicone and mineral plasters are used, but acrylic mixtures, which become a vapor barrier, are not used.

In addition, it is better not to insulate wall materials with high vapor permeability (ceramic bricks, ceramic blocks and aerated concrete) with polystyrene foam at all, leaving it to insulate silicate bricks, concrete and foundation structures.

Insulation of the facade with mineral wool

The popularity of thermal insulation of the facade of a house with mineral wool is due to the many advantages of this material. It has many useful properties that make home insulation effective. Mineral wool is often used in the design of the outer walls of buildings and serves as a good insulation.It is lightweight, extremely easy to install, and also exhibits excellent thermal insulation characteristics. Also worth noting is its reasonable price. You can lay it yourself if you are competently versed in the technology and nuances of the process. Facade insulation technology provides for the use of various insulation materials, among which mineral wool takes pride of place. The material is able to perfectly protect the external walls of buildings from freezing. This is the best option for a ventilated facade system made of stone or porcelain stoneware. For the wet facade technology, this type of insulation is also used. It will not be difficult to buy it. In Moscow, mineral wool slabs are presented in a wide range.

Savings on glue and other components

A set of components for wet insulation of facades can be purchased as a set or formed independently. Any set includes an adhesive mixture for fixing thermal insulation, insulation and dowels for fixing insulation, reinforcing mesh, building mixture for reinforcing insulation and plaster.

Choosing the components on their own, some craftsmen believe that the insulation does not have to be glued to the wall, but it is enough to attach it with dowels. In other cases, it is suggested to replace the adhesive mixture for the insulation with a cheap solution (for example, tile adhesive) or simply save on the application of glue.

But a wall insulated in this way is likely to begin to collapse. Cracking of the plaster, peeling and tearing of thermal insulation, etc. will occur. External insulation of facades is performed for a long time, and it is better to give up saving, not to reduce the amount of glue and not to dilute it with sand.

Another problem is the wrong choice of dowels for facade systems, which must withstand the corresponding loads, changes in humidity and temperature, the influence of the external environment, etc. The choice of fasteners should be determined by the wall material, the type and thickness of the insulation. At the same time, not only the quality of the dowels, but also their quantity are important for fixing the thermal insulation.

Basalt insulation for the facade in Moscow

Composition and difference from glass wool

While glass wool is made from materials used in glass production (dolomite, quartz, sand, etc.), stone wool is made of basalt. It is a rock of volcanic origin. In fact - a stone. This stone is melted and made into cotton wool in a manner similar to the production of cotton candy.

Facade basalt wool has a chaotic fiber structure, which results in an extremely low thermal conductivity coefficient. This is the main advantage of basalt.

Since stone wool is much denser than glass wool, it is made in the form of basalt slabs to insulate the facade. Manufacturers adjust the dimensions to the parameters of the substructure most popular with builders to make it easier to install. The standard width of the slabs reaches about 600 mm, the length is most often no more than 1200 mm, and the thickness of such slabs can be from 30 to 150 mm.

In addition, basalt insulation for the facade is denser than fiberglass. Due to this, it is not subject to shrinkage, but also has a greater mass.

Benefits

Before buying basalt insulation for the facade, you need to know its main advantages:

- Fire safety

... Such insulation does not burn. It may melt over time, but it will not ignite. That is why it is considered another stage of fire protection. - Chemical passivity

... Chemically aggressive substances almost do not harm the basalt facade insulation. - Ease of installation

... Facade basalt slabs are easy to install on any substructure due to the thought-out dimensions and the ability to cut the slab. - Soundproofing

... Stone wool fibers are excellent at dampening noise from the outside.This will make the house quieter. - Excellent hydrophobicity

... Basalt insulation for the facade perfectly repels water. The less the insulation gets wet, the better it retains its properties. - Non-toxic

... In the production of basalt insulation, phenols, formaldehydes or resins are not used - due to this, it does not emit harmful substances. - Rodent resistant

... Small animals do not eat stone wool. - Resistant to aggressive environments

... Stone wool almost does not deteriorate, even if chemically aggressive substances have got on it.

What happens if you ignore the thermal insulation?

The owner of the house, who decided not to use basalt or any other insulation for the facade, may face a number of troubles:

- The house will be cold in winter

... A house without thermal insulation freezes faster in winter. This will require more heating, which can lead to higher heating bills. - It will be hot in summer

... The cladding of the facade in summer can be very hot from the sun's rays, warming up the air inside the house. It turns out that without insulation in the summer it can be very hot in the house. - High humidity

... Higher temperatures in summer lead to increased humidity. There is a chance that a fungus will develop in the house, which is dangerous for the health of all residents, especially for children. - Increased noise

... Since the insulation will not dampen sounds from the outside, it will be more noisy inside the house. This will be especially noticeable if the building is located near the road.

Summing up

Basalt slabs are a good option for facade insulation. They are non-toxic, do not burn, and do not absorb much moisture. They are easy to install, and most importantly, they are excellent at keeping your home warm and save you money on heating bills.

You can find out the price of basalt slabs for the facade in the Metal Profile online store.

Incorrect installation of insulation

When installing a wet facade insulation system, you should try to avoid the most common mistakes in fixing elements. These include, first of all, a loose joint of insulation boards, as well as filling the joints with glue. And in fact, and in another case, this leads to the formation of cold bridges and cracks in the finish coating. Therefore, when installing thermal insulation boards, gaps of more than 2 mm must be filled with strips of thermal insulation material.

It is very important to make a monolithic thermal insulation loop around the entire house. Close attention is paid to the most difficult places - corners, niches, ledges, openings. Here you need to perform an elastic abutment of the elements to the wall and protect it from moisture penetration.

When installing the insulation, it is important to place the dowel caps flush with the outer surface of the thermal insulation layer. Otherwise, bumps or depressions will appear on the finishing plaster, which will also worsen the design characteristics of the system.

We cover the mineral wool with plaster using the "wet facade" technology

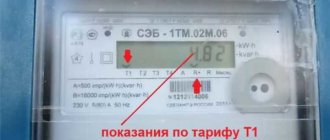

Source: domzastroika. Owners of private houses often use electric heaters to maintain a comfortable temperature in the room. But if the building is not sufficiently insulated, then heat leakage occurs, as a result of which a lot of electricity is consumed.

To solve this problem, experts recommend insulating facades with mineral wool. This will keep the room warm, protect the walls from adverse natural factors and help to perform a decorative function. To make the installation of mineral wool with your own hands, it is recommended to study the technical characteristics of the material and delve into the essence of the process technology. When insulating the facade of the building, special mineral wool is used, intended for outdoor use.

Compared to insulation for interior work, it is more durable, dense and moisture resistant. Facade mineral wool is sold in mats or slabs, the dimensions of which can be 50x cm and 60x cm.

Cotton wool for a wet facade is a means for insulating structures. The use of such a material for a construction site is a complex action that is designed to solve many problems.

When choosing a material, you should pay attention to its density, which should be at least 80 kg per cubic meter. Today the construction market offers a lot of materials with which you can insulate various buildings.

Incorrect insulation reinforcement

One of the mistakes of wet insulation of facades is the laying of a reinforcing mesh directly on the insulation, and not in a layer of glue. This installation usually leads to delamination of the reinforcing layer.

The mesh should be embedded in the adhesive layer, providing an overlap of at least 100 mm in all directions, after which a second layer of waterproof reinforcing composition is applied over the mesh.

In addition, the mesh itself must be alkali-resistant (cement-based mortar has an alkaline reaction), have a density of 160 g / m2 and a mesh of 3 × 3 mm or 5 × 5 mm.

Density of mineral wool for various surfaces

This insulation has a fairly low price and good functionality. This variety is one of the most versatile. KMV is distinguished by the best heat-insulating, sound-insulating characteristics. It is also highly resistant to fire. KMV is very often used in domestic and industrial construction. Differs in reasonable price and high quality. It is produced from the melted waste of the metallurgical industry.

Of the main characteristics, it is worth noting the highest reliability throughout the entire period of long-term operation. As a rule, slag mineral wool is in the form of slabs, special shells. In the organization of a slag insulation system, neutral phenolic binders are used. Wool for a wet facade must be non-combustible, have high moisture-repellent properties and other above-mentioned characteristics.

Thus, mineral wool is one of the best materials for insulating facades. Due to its relatively high price, mineral wool is very popular.

Its functional characteristics are worth the cost many times. Website creation and promotion.