Duct classification

Duct design affects the connection method

System design influences the choice of connection method. Also, the docking method depends on the operating conditions, the parameters of the removal of polluted air.

Round and rectangular

Round and rectangular structures are distinguished by their geometric shape. The advantage of the first option is that there is no risk of vortex flows. The noise level is lower here. This type of duct is more often used in industrial premises.

For residential buildings, a rectangular design is better. Thanks to its high flow capacity, it provides good ventilation. It is easier to hide such a system under the finishing material. Due to its tight fit to the wall, the product does not take up much usable space.

In rare cases, elements of a triangular section are used to form an air conditioning system. They matter for the interior.

Rigid and flexible

Example of a rigid duct made of plastic pipes

Rigid air ducts have different shapes: round, square, rectangular. For the manufacture of the structure, aluminum, stainless steel, and polymer materials are used. Flexible options are only round in shape. They are made from aluminum, textile, PVC. To give additional rigidity to the product, wire is used. An efficient system combines both types of ductwork.

Air ducts are located inside the wall or outside it. The first option is a ventilation shaft in a capital structure. It is used in residential areas. An external duct is more suitable for industrial or technical areas where design is not always important.

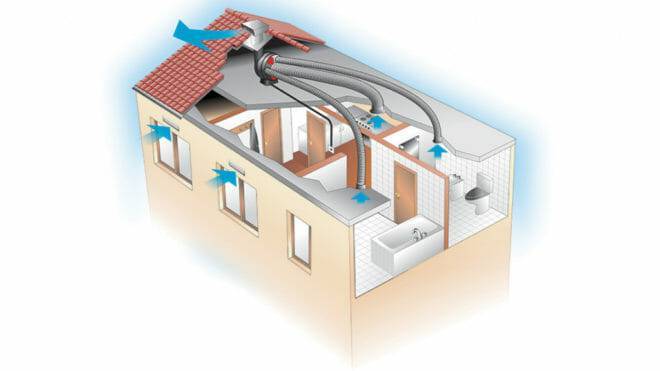

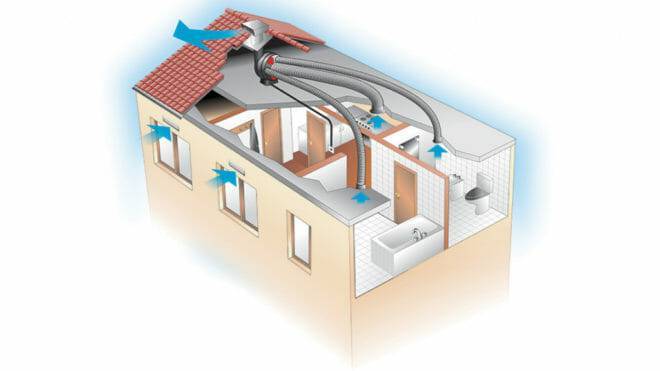

Installation of the ventilation unit

An air handling unit is a prefabricated ventilation unit for supply and exhaust ventilation controlled by a controller. It is mounted on brackets on interior walls and ceilings.

The main type-setting elements of the installation: controller, air ducts, fans, heaters, filters and noise absorbers.

The controller is used to set the temperature parameters, noise level, and the intensity of the fans. More advanced systems are connected to the “smart home” system and can adjust the level of filtration, set operating modes at different times of the year or even days.

Main characteristics:

- performance;

- static pressure;

- noise level;

- filtration degree;

- system functions.

In standard apartments 35-60 sq.m. you can focus on the productivity of 200-350 cubic meters / hour; 70-130 sq.m. - 300-500 cubic meters / hour.

Static pressure depends on the degree of complexity of the air route, the number of filters and grilles, for apartments up to 90 m2 - from 450 Pa.

In addition to the typesetting elements for rooms up to 100 m2, the option of an individual portable installation is possible.

Welding methods

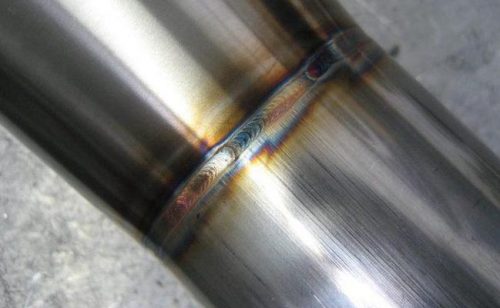

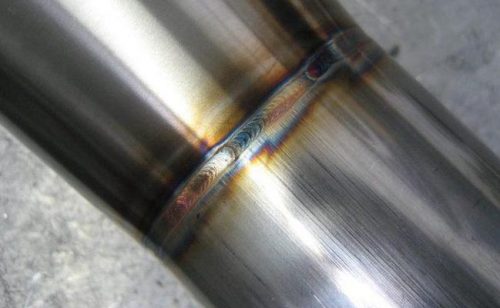

The welded method of connecting the duct is considered the most reliable

The craftsmen do not often have to connect the air ducts to each other by welding, since the process is expensive. This method is used if special requirements are imposed on the tightness of the structure. The welding process can be manual or mechanized.

Manual

Electric arc welding is used if the material thickness is more than 1.5 mm. Gas equipment is necessary if the metal is 0.8 mm thick. The second method is rarely used.

Mechanized

The mechanized welding method can be semi-automatic or automatic. It is used in businesses.

Connection types

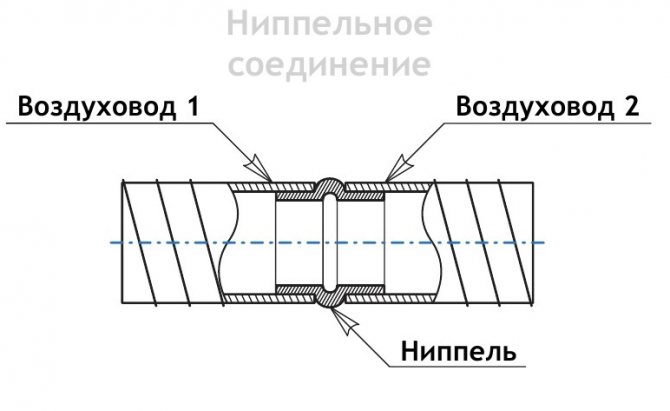

Duct nipple connection

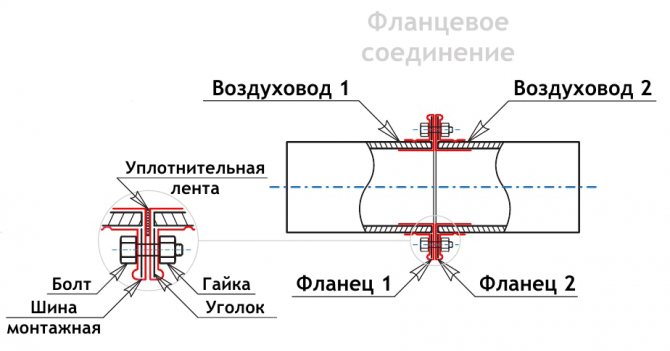

The connection of ventilation pipes to each other is carried out by a welded or flanged method. In addition, the elements can be fixed with a bandage, nipple or sleeve.

Welded

It is possible to connect fragments of the air duct by welding if they are metal, while the thickness of their walls exceeds 1.5 cm. This method is most often used in industrial premises in which harmful gases accumulate. In this case, the seams should be as tight as possible. For galvanized materials, highly professional welding is required to avoid corrosion in the seam area.

Nipple

A nipple is a part of a pipe with a raised rib in the middle. It is inserted into the main structure. The same rib is used for fixation. Another section of the duct is put on the product. The joint is sealed with metallized tape.

The nipple connection is carried out using a sleeve. Its diameter is larger than the main pipe. The coupling can combine 2 structural fragments. The rib in this case is on the inner surface of the element. This method is used to connect round ducts.

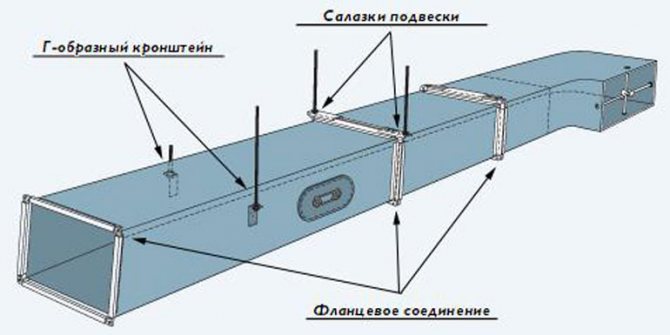

Flanged

Flange for joining two parts of the duct

According to GOST, pipes can be connected using the flange method. For fastening parts, spot or solid welding is used. The flanges are fixed between themselves with nuts and bolts, as well as rivets. To ensure reliable sealing of the weld, it must be painted over. A sealing gasket is placed between the steel elements. Although efficient, flanged duct connections are labor intensive and expensive.

Bandage

The bandage method of joining the structure is in demand at chemical industry enterprises. It provides high reliability of the joint, but the manufacturing process itself is expensive, therefore it is unpopular for domestic use. The bandage is attached over the connecting seam. Before this, the ends require flanging. The bandage space is filled with a chemically inert sealant. This method is used to connect plastic ducts to each other.

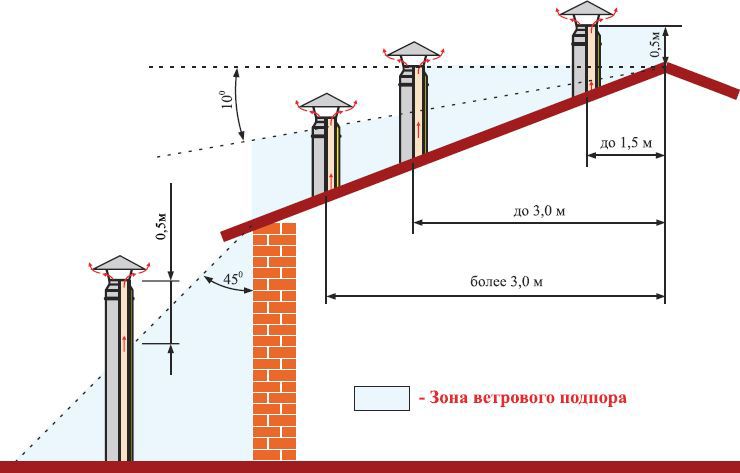

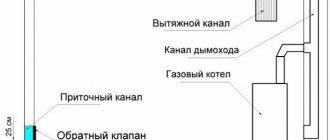

Ventilation ducts

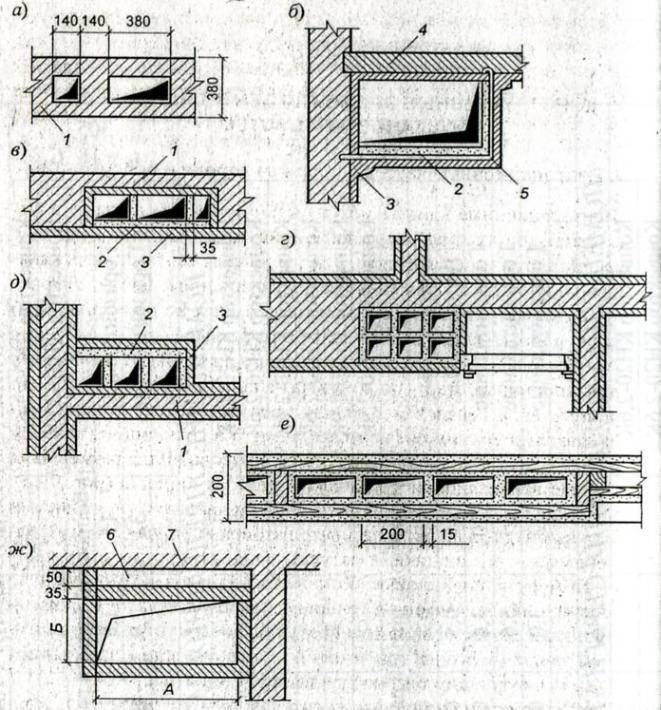

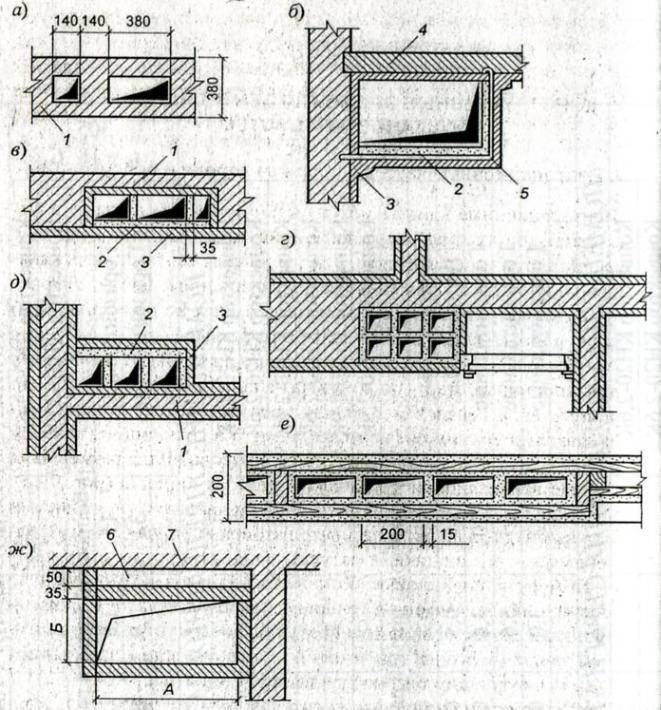

The ventilation ducts can be laid in the thickness of the inner walls, or made in the form of side ducts from slabs near the inner walls and partitions. For the construction of vertical ducts, special ventilation blocks are also used (Fig. 8.7 and 8.8). The installation of ducts is not allowed in the outer walls in order to avoid condensation of water vapor of the removed air in them.

The minimum cross-section of ventilation ducts arranged in the thickness of brick walls is half a brick on a half brick (140x140 mm). The thickness of the walls of the channels and the thickness of the walls between the channels of the same name are assumed to be no less than half a brick, therefore the smallest thickness of the inner wall suitable for placement in its thickness of the ventilation channel is one and a half bricks (Fig. 8.7. A). The thickness of the walls between opposite channels (supply and exhaust) should be at least the size of a brick (250 mm), the same size - half a brick, and the dimensions of the channels should be multiples of the size of half a brick. The arrangement of channels is also possible in internal walls with a thickness less than 1.5 bricks. But in this case, it is necessary to provide for the device of a vertical niche (furrows or grooves), which is then sealed with a slab, followed by plastering the wall (Fig. 8.7.c).

In the absence of brick capital internal walls, ventilation panels are installed or channels are made attached (vertical and horizontal) from blocks and slabs (slag-gypsum and cinder-concrete, concrete, etc.).The minimum section of the side ducts is 100x150 mm. Additional ducts can also be placed near the outer walls, but in this case there must be an air gap of at least 50 mm thickness between the duct and the outer wall (Figure 8.7.g) or a layer of insulation, the thermal resistance of which is sufficient to prevent condensation of water vapor in the duct.

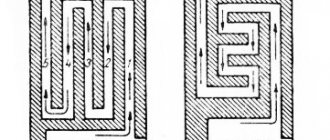

Fig. 8.7. ventilation duct designs

a - in a brick wall; b - suspended horizontal; c - in the furrow of the wall, covered with a slab; d - configured with a built-in wardrobe; d - attached (wall) vertical; e - in a partition sheathed with sheets of dry plaster; g - side channel near the outer wall.

1 - brick wall; 2 - slag gypsum boards; 3 - plaster; 4 - overlap; 5 - suspension from steel strip and wired = 6 mm; 6 - airtight air gap; 7 - outer wall.

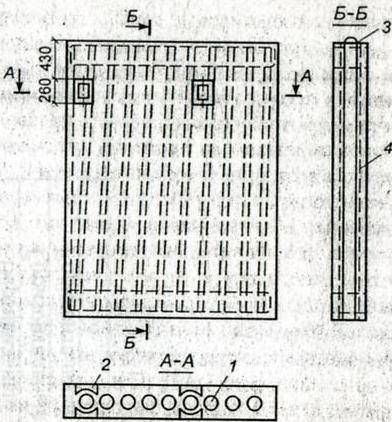

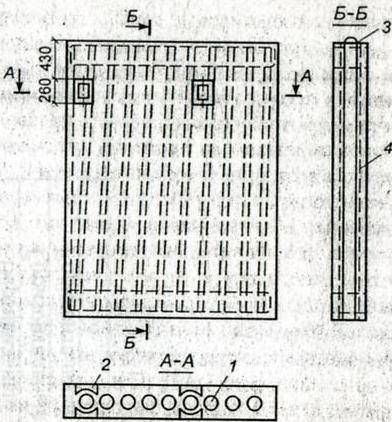

A design feature of some ventilation panels is the presence of a channel for the transit movement of air from the underlying floors to the exhaust shaft.

Fig. 8.8. Ventilation block-panel with inclined ducts

1 - exhaust duct; 2 - a recess for installing a louver grille; 3 - wire loop for block transportation; 4 - metal reinforcing mesh.

Used equipment and materials

Contact welding machine for manual connection of stainless steel air duct

To create a nipple connection of ducts or a welded joint, the following tools and materials are required:

- stainless steel;

- tape measure, marker;

- hammer, pliers;

- vice;

- tools for cutting metal;

- sealant and a gun for its application;

- welding machine;

- pipe fragments of the corresponding diameter.

The construction assembly technology must be observed to the smallest detail. If you combine parts of the duct without sealing, the functionality of the system is impaired. The connection of the structure to the hood is carried out taking into account the diameter of all parts. Before the installation of the air duct, its drawing is made.

Use of sewer pipes

A galvanized ventilation pipe 100 mm and 110 mm is used for laying the air ducts. Polymer parts have the same diameters. Pipes intended for the arrangement of the sewage system (for example, the corrugation connecting the sewer outlet to the pipe) are 120 mm in size.

The question arises, is it possible to use drain pipes and corrugations for arranging ventilation ducts, because their price is much lower?

Here you should be guided by the following rules:

- The outlet must be wider than the inlet ventilation duct. Therefore, it is highly discouraged to attach 120mm corrugation to 110mm ventilation.

- Many believe that such a transition does not affect the functionality of the ventilation. They seal the joint with tape, sealant and other similar materials. However, the air flow passing through such a step will create turbulence, which will greatly reduce the efficiency of the system.

- If it is necessary to equip the transition, you should use adapters with a smooth taper, which will ensure the unhindered passage of the air flow.

Sewer pipes can sometimes act as ventilation

Advantages and disadvantages of a welded connection of air ducts

If the weld is poorly done, it will come loose over time.

The welded joint is one-piece and does not require additional fixing elements. It has the following advantages:

- the ability to manufacture large-sized structures;

- reduction in weight compared to cast elements;

- high strength and reliability of the joint;

- relatively low labor intensity in domestic conditions.

Residual stress often occurs in the welded joint.In this case, the technical properties of the metal change, which eventually loses its strength. If welding is used ineptly, the seams may be defective. After using the device, the joints must be checked visually and with the help of tools. Local heating of the metal in the heat-affected area can change the mechanical properties of the material.

Scope of application

Correct seam ensures long-term trouble-free ventilation

You need to connect air ducts to the hood in any room. Welded joints are used in systems for removing fumes, moving air saturated with moisture or acid fumes. They are necessary in structures with high pressure inside or hot air masses circulating.

This type of connection is used in basements, attic floors. It is suitable for residential and technical premises. This type of installation of air ducts is fireproof, durable and sealed.

The welded connection of the duct allows for good ventilation. However, the work must be carried out strictly according to the instructions.