Basalt heat-insulating plate of the Optimal 50 series, as deservedly received this name. This is really the best option for solving most of the problems with the insulation of various buildings, structures and their individual elements.

This insulation balances between good insulation efficiency and the comparative cheapness of the material itself (the Ventfasad series also has similar characteristics).

Heat insulator "Izover Optimal

«

And for those buyers who find the scope of application of the Optimal 50 series too narrow, the manufacturer has provided a modified and more efficient version with the name Isover Ruf N Optimal 50. However, it is the classic insulation "Isover Optimal" that has gained immense popularity.

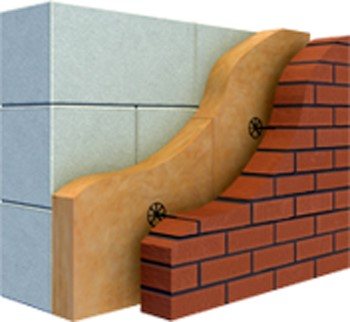

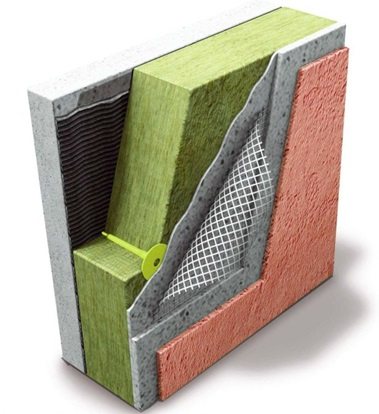

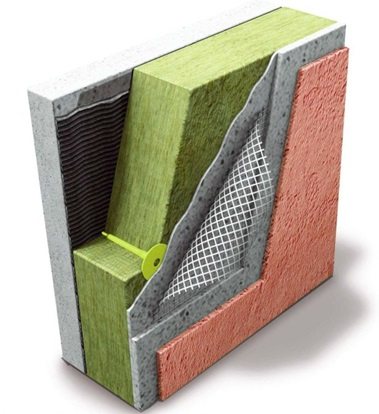

Plan of stages of work on the system of facade insulation with a thick plaster layer

- Preparatory work

- Installation of scaffolding

- Removing attachments

- Preparation of window openings

- Installation work

- Mounting fixing system

- Installation of mineral wool boards

- Installation of metal tiles

- Base coat application

- Application of a leveling plaster layer

- Applying a decorative layer

You can start cutting the expansion joint after applying decorative plaster. Cutting occurs along the corners of the building at a distance of 250 mm, along the surface in squares of 15 * 15 m.Produced by an angle grinder with a diamond disc

Isover. Which insulation is better: in slabs or in rolls?

Isover. Which insulation is better: in slabs or in rolls?

In this video you will find out which insulation is easier to work with: in slabs or in rolls. The main characteristic showing the quality of the insulation material is its recoverability. High-quality material has the ability to recover to the declared size after opening the package, which was demonstrated in the video. The thickness of the Isover insulation both in slabs and in rolls after opening the package recovered to 50 mm. To install the insulation in the slabs, it is necessary to measure the distance between the frame posts. Plates are ideal for wall insulation with a standard distance between the frame posts - 600 mm. When installing the slabs, joints are formed, which must be covered with a second layer of slabs. It is better to use insulation in rolls with a non-standard step between the frame racks. First, the distance between the posts is measured, then the unpacked roll is cut to the required size and rolled out along the entire length of the wall. When insulating with rolls, no joints are formed. All Isover materials have increased elasticity and are securely held in the structure.

Isover: How safe are thermal insulation materials?

Isover: How safe are thermal insulation materials?

In this video, you will learn how safe the use of mineral wool is for your health and the health of your family. The safety of mineral wool has been confirmed by eco-labels, as well as studies in large scientific centers, such as, for example, the Institute of Hygiene. Sysina. In addition to these guarantees, Isover provides an environmental declaration for its products. Thermal insulation based on mineral wool is used in all buildings and structures, including kindergartens, schools, hospitals. Another sign of the absolute safety of mineral wool is its incombustibility and fire safety, which is confirmed by certificates of compliance with fire safety requirements.

Isover: Which insulation is better: stone wool or fiberglass?

Isover: Which insulation is better: stone wool or fiberglass?

Isover is the only Russian company that produces mineral wool based on fiberglass and stone wool. The basis of stone wool insulation is molten rocks, and the basis of fiberglass insulation is sand and cullet melted at 1000 ° C. Materials based on stone fiber are denser than materials based on fiberglass, which is primarily due to the length of the fibers in the production of the base for the insulation. But density is not a determining parameter when choosing a heater. The main characteristics are thermal conductivity and mechanical characteristics. If we compare materials by field of application, insulation based on both types of mineral wool is divided into three types: Light grades are used in frame structures, for insulation of walls, pitched roofs. Such insulation does not take on any load. Rigid grades are used in plaster facades, flat loaded roofs. Highly specialized materials are used for soundproofing partitions and for insulating saunas and baths. Materials based on fiberglass are lighter than materials based on stone wool. Due to the length of the fibers, they have greater elasticity, which allows filling all irregularities and voids of the insulated surface, eliminates the formation of "cold bridges" and ensures reliable fixation in the structure. Both types of materials are non-combustible materials, do not spread or sustain combustion. Now that you know the differences between the two types of mineral wool, you will make the correct and objective choice of thermal insulation material for your home.

Isover: Is the density of insulation materials important?

Isolite

Isolite (Izoroc) Is a heat-insulating material in the form of special slabs made of rock-based mineral wool.

Insulation has unsurpassed properties and also provides sound insulation. The scope of its application covers a wide range of structures of buildings and structures - horizontal, vertical, as well as with any angle of inclination.

Isolite is unrivaled and is successfully used for:

- two-layer insulation;

- construction of structures with a ventilation outlet to create an inner layer;

- in the construction of multi-storey buildings, in order to provide high-quality insulation between floors;

- erection of lightweight masonry;

- construction of frame houses and partitions in them;

- installation of equipment, the heating of which is more than 400 degrees Celsius, in order to create an insulating layer.

The composition of the Isolite material is unique. Thanks to this, very high insulation values are achieved, which ensures a reduction in energy consumption and maintenance of a comfortable microclimate in the room, during the construction of which this insulation was used.

There are two types of Isolate:

- Isolight-L;

- Isolight-Lux.

Their characteristics differ in terms of density, which is 40 and 60 kg per square meter, respectively. From these indicators, we can conclude that this insulation is much denser than other building materials in this category. The rest of the parameters regarding the dimensions of the slabs are the same for Isolight-L and Isolight-Lux.

Sound insulation of this insulation is provided by a special structure based on fibers of different lengths that absorb absolutely all extraneous noise.

Isolite has another useful property - it is hydrophobic. Due to a special water-repellent layer, the insulation prevents the accumulation of moisture, which contributes to the durability of the structures.

As for the factor affecting health, in this regard, the material is absolutely harmless and environmentally friendly, does not emit toxins.Therefore, it can be safely used to insulate your home.

Talking about this building material, it is pertinent to note that the process of its installation is very simple due to the fact that it is easy and free to cut. Therefore, insulation with the help of Isolate can be done independently, without resorting to the services of specialists.

You can profitably purchase Isolight of any type from us. Sale of insulation is carried out both at retail and wholesale.

Isover: Is the density of insulation materials important?

Is the density of mineral wool insulation a decisive characteristic when choosing a heater? You will find the answer to this question in this video. The density of the insulating material affects the coefficient of thermal conductivity, strength characteristics and other parameters. But this relationship is not linear. The dependence of the thermal conductivity coefficient on the density of the material is the same for fiberglass and stone wool. For fiberglass-based insulation, the range of optimal density that provides the minimum thermal conductivity is 25-35 kg / m3. For insulation based on stone wool - 45-55 kg / m3. Thus, stone wool is able to provide the same thermal insulation characteristics, but at higher densities. Remember that by purchasing thermal insulation materials, we acquire the thermal insulation qualities of the product, not its density. Even a lightweight fiberglass insulation board with a density of 60 kg / m3 is able to withstand heavy loads without deformation. Therefore, when choosing a heater, first of all, pay attention to the coefficient of thermal conductivity, durability, incombustibility and environmental friendliness.

Basalt heat-insulating plate of the Optimal 50 series, as deservedly received this name. This is really the best option for solving most of the problems with the insulation of various buildings, structures and their individual elements.

This insulation balances between good insulation efficiency and the comparative cheapness of the material itself (the Ventfasad series also has similar characteristics).

Heat insulator "Izover Optimal

«

And for those buyers who find the scope of application of the Optimal 50 series too narrow, the manufacturer has provided a modified and more efficient version with the name Isover Ruf N Optimal 50. However, it is the classic insulation "Isover Optimal" that has gained immense popularity.

Vapor permeability coefficient

The characteristics of insulating boards inspire confidence in buyers and are not inferior to expensive counterparts, which are presented in the building materials markets. They are distinguished by a coefficient of thermal conductivity ranging from 0,036 W / (m * K) up to 0,042 W / (m * K).

Insulation Isover Optimal is often used in housing construction and even in wooden houses, as it belongs to the class of non-combustible materials. The main advantage is the ease of installation, which does not require additional fastening. Mats can be shot with a stapler or inserted into special slats.

The vapor permeability of the mats is at least 0,30 mg / m * Pa. This indicates resistance to water penetration, which guarantees protection against mold and mildew, which often affect similar products from the low-cost segment of the market.

The scope of application of Isover Optimal in private houses is quite extensive:

- for pitched roofs and mansard floors;

- for floors on installed lags;

- in the construction of suspended ceilings;

- for interfloor floors;

- for frame walls;

- for interior partitions.

In addition, it is extremely difficult to find insulation warmer than Izover Optimal in a similar segment in the building materials markets. In addition to excellent thermal conductivity, it has good sound insulation.

Main operational characteristics of Isover Optimal slabs

- Resistance to stress and deformation. The density of the material is in the range of 28–40 kg / m³.Due to this, the plates retain their geometric shape throughout the entire period of operation.

- Excellent thermophysical parameters. The insulation has a low thermal conductivity - no more than 0.042 W / (m * K). This significantly reduces heat losses.

- Low water absorption - no more than 1 kg / m² at partial immersion in 24 hours.

- Fire resistance. The material belongs to the group of non-combustible insulation materials.

- Noise absorption. The fibrous structure effectively traps sound waves.

Isover for roof insulation

The number of materials for thermal insulation is constantly growing. More and more consumers are realizing the need to insulate walls, roofs and foundations of private houses and other buildings. The technical characteristics and advantages of Isover insulation induce some to use this particular material. What he really is? What are the advantages and properties?

Isover OPTIMAL (ISOVER Optimal) Mineral wool

Min. ISOVER wool in the construction market has been used for a long time and has established itself as an excellent insulation that does not require special costs and skills during installation, which is especially important in individual residential construction. Produced by a French concern with production in the Moscow region. Min. Wool is used to insulate walls and floors. Due to its low density, it has a high degree of sound insulation and low thermal conductivity. Mineral wool products ISOVER OPTIMAL are widely used to improve the thermal insulation properties of floors, load-bearing walls, pitched roofs and suspended ceilings, as well as independently as a heater. Suitable for prefabricated and frame construction. Convenient for use in layered masonry and in the installation of ventilated facades. Available in various thicknesses, which allows you to easily select the material and reduce costs. ISOVER OPTIMAL is produced in slabs with dimensions 600 \ 1200mm, thickness 50-100mm in a package of 8 and 4, respectively. Compared to roll material, it has a high density, moisture resistance, however, you should not neglect vapor and moisture insulation, since when the material gets wet it loses its properties.

Plates are also used for insulating pitched roofs, when installing partitions. Due to their dimensions, they are easy to install in combination with finishing materials, which is especially convenient when working with drywall and glass-magnesium sheets.

ISOVER OPTIMAL is made on the basis of basalt rocks due to which it is nonflammable according to GOST NG, environmentally friendly, thermal conductivity is 0.036, which is an order of magnitude lower than that of wood. In professional construction, it is widely used in rapidly erected buildings, frame construction, if necessary, at the request of the customer, it can be made of the required dimensions, it is used in layered masonry. Also, this material is widely used for the installation of ventilated facades, as it is non-combustible, easy to attach, and cut with an ordinary wallpaper knife.

In private construction, it is especially worth noting the use in the arrangement of attic rooms, especially in already built houses. ISOVER OPTIMAL is the optimal, and in some cases the only option. The use of this material minimizes floor loads. Low thermal conductivity will allow you to live indoors even in Siberian frosts. The service life is not less than 25 years.

The main properties of ISOVER OPTIMAL mineral wool products: 1. Possesses a high level of heat retention. 2. It is characterized by high soundproofing qualities. 3. Resistant to high temperatures and direct fire. 4. Do not expose the boards to direct exposure to steam and high humidity, failure to comply with this condition may lead to the loss of the basic properties of the material. 5. Hides visible defects of working surfaces. 6. Easily combined with various finishing materials (plasterboard, glass-magnesium sheets). 7. Simplicity and availability of products during installation work. 8. It does not need additional fixation during installation. 9.It is characterized by high environmental friendliness.

Technical characteristics of ISOVER OPTIMAL mineral wool products: ISOVER OPTIMAL mineral wool products are made on the basis of basalt rocks. 1. Average dimensions of slabs - 1200 * 600 * 50 (100) mm. 2. The average value of the coefficient of thermal conductivity is 0.036-0.040 W / m * K. 3. The average level of vapor permeability is 0.3 mg / (m * h * Pa). 4. The level of water absorption in case of partial contact with water within 24 hours is no more than 1 kg per sq.m. 5. Refers to non-combustible substances - NG group. 6. Operation of products in a wide range of low temperatures is possible.

AMAKS recommends:

In order to save money, to insulate the facade, you can use Isover Optimal in combination

- Isover optimal 100 mm

- Izover VENTI 50 mm

What is Isover insulation?

This insulation is represented by mineral wool - a fibrous material that is made in the form of slabs, rolls and mats. The thickness of the glass fibers is 4-5 microns, and the length is 100-150 microns. For production, only natural ingredients are used, so there is no need to worry about the environmental friendliness of the material.

Plates can be rigid or semi-rigid. Insulation is mounted both horizontally and vertically, both during interior work and when arranging facades.

Isover

It is made from sand (quartz) and broken glass. To improve certain properties, soda, borax, limestone and other components can be added to the material. The entire mass is poured into a special hopper. The process of melting the ingredients takes place there. When molten glass is ejected from the centrifuge, it forms strands due to the blowing of the steam. When hitting the rolls, the aerosolized filaments flatten out and form a carpet. Then, at + 250 ° C, the polymerization process takes place. When the material cools down, it is cut into rolls, mats and slabs.

Specifications, advantages and disadvantages

Since insulation is the main role of Izover, it is worth paying attention to its thermal conductivity. The coefficient of thermal conductivity is within 0.038 W / (m * K). Other advantages include the following factors:

- Good soundproofing. Using mineral wool in the interior partitions, you can achieve a good effect.

- It is not eaten by rodents and insects. Therefore, using such material for the facade, you can not be afraid that subsequently holes from rodents will appear in it.

- Ease of installation. This material is produced in various forms, so you can choose exactly the one that will be optimal for the work being done.

- Long service life - 50 years.

- The material does not deform in compression and has tensile strength. Due to its good compressibility, it is easy to transport.

- Resistant to extreme temperatures.

- The insulation is not flammable, therefore it meets the high fire safety requirements.

Ceiling insulation

Disadvantages of the material:

- The need to use protective equipment during installation work. Although over time there will be no harm from mineral wool, when installing thermal insulation, it is necessary to protect the respiratory system.

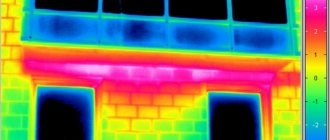

- High moisture permeability. When wet during operation or during installation, heat-shielding properties will be lost. Therefore, when dealing with facade work, the mineral wool must either be covered or covered with a layer of plaster as soon as possible after installation. This will prevent the harmful effects of rainfall.

Safety precautions when working with mineral wool

Mineral wool Isover Facade Light 50 х 600 х 1200 mm 5.76 sq.m

ISOVER Facade Light are rigid heat and sound insulation boards made of mineral wool based on fiberglass. Specially adapted for use as part of facade systems with a thin plaster layer in low-rise buildings. The material ensures the reliability and durability of plaster facades.

Technical data:

Thickness - 50 mm, Width - 600 mm, Length - 1200 mm

The amount of material in the package - 6 pieces, The area of the material in the package - 5.76 m2, The volume of the material in the package - 0.288 m3

Thermal conductivity 10 ± 2 degrees, 10, no more - 0.037 W / (m * K) according to GOST 31924-2011

The calculated value of thermal conductivity under operating conditions A - 0.04 W / (m * K) according to SP 23-101-2004

The calculated value of thermal conductivity for adj. E operating conditions B - 0.042 W / (m * K) according to SP 23-101-2004

Compressive strength at 10% relative deformation, not less than 30 kPa according to GOST EN 826

Tensile strength perpendicular to the front surfaces, not less than 10 kPa according to GOST EN 1607

Water absorption, with short-term and partial immersion, no more than 1 kg / m2 according to GOST EN 1609

Water vapor permeability - 0.40 mg / m * h * Pa in accordance with GOST 25898

Flammability group - NG in accordance with GOST 30244

APPLICATION AREA

Thermal insulation layer in the structures of thin-layer plaster facades for cottage and low-rise construction

ADVANTAGES

The only rigid fiberglass slabs: strong, lightweight, easy to install

Reliable thermal protection of your home due to the low thermal conductivity coefficient? = 0.037 W / m * K

Professional solution specially adapted for private housing construction

Safe for human health and the environment: allowed for use in kindergartens and preschool institutions

Fire safety: belongs to the group of non-combustible materials (NG)

INSTALLATION RECOMMENDATIONS FOR SFTK WITH THIN PLASTERING LAYERS

1. Thermal insulation boards are fixed to the base from the bottom up, starting from the support (basement) profile.

2. Before applying the adhesive, it is recommended to prime the surface of the insulation board with a thin layer of the same adhesive.

3. Thermal insulation boards are fixed to the base of the wall with an adhesive and additionally fixed with disc anchors.

4. The contact area of the adhesive composition with the base after the installation of the thermal insulation board in the design position must be at least 40%.

5. After applying the adhesive, the slab is immediately installed in the design position, the excess of the protruding composition is removed. The correctness of the installation of each thermal insulation plate in the design position is controlled by a level of 2 m long.

6. Installation of thermal insulation boards should be carried out close to each other. If, after installing the plates, gaps with a width of more than 2 mm remain, they must be filled with a uniform layer of heat-insulating material.

7. Fastening of heat-insulating plates with anchors is carried out only after the adhesive composition has completely dried.

8. The plate anchor is installed flush with the surface of the thermal insulation layer.

9. At the corners of window and door openings, heat-insulating plates with a corner cut should be installed so that the joints between the adjoining plates are at a distance of at least 100 mm from the corner of the opening.

10. It is not allowed to bend the thermal insulation plates in order to insulate the corner zone. To solve this problem, the slabs must be installed with bandaging of each layer.

IMPORTANT

According to the recommendations of the system holders, the installation of the facade should be started if:

1. average daily outside air temperature non-average outside air temperature not lower than +5 degrees below +5 degrees;

2. all the “wet” processes have been completed: the interior finishing is finished, the floor screed is laid and dried;

3. the facade of the building and the place of work are protected from possible ingress of water both from above and from the side;

STORAGE

The material should be stored in a dry, covered room, isolated from direct sunlight, and packed. It is allowed to store under a canopy or in an open area on pallets in polyethylene covers or other packages that completely protect the boards from the effects of precipitation. The stacking height during storage should not exceed 5 m.Warehousing in several tiers is allowed, provided that the safety and security requirements of the product are met.

Types of Izover

Due to the wide variety of forms, Isover mineral wool is used in various fields. When building a house, it can be used to insulate ventilated facades, attic, floors, ceilings and internal partitions. Each model has its own purpose and is used in a specific area, so it is difficult to give a general description of the material. You can still consider each species separately.

Isover Optimal

Its density is 28-37 kg / m 3. It comes in the form of slabs. It is used for a frame house. They can insulate the roof, floors, and walls. It is used as sound insulation for interior partitions and floors between floors. The dimensions of the slab are 60 * 100 cm, the thickness is 5 cm or 10 cm. One package contains 4 slabs (10 cm) or 8 slabs (5 cm).

Isover Roof V Optimal is produced in a thinner thickness of 3 or 5 cm. In most cases it is used for flat roofs. Despite the small thickness of the material, its structure is homogeneous. It can withstand a load of 7 tons per 1 m 2.

Isover Standard

This model is used for thermal insulation of facade walls before cladding with siding or facing bricks. They are also sheathed with frame structures. They are produced with the same dimensions as the Optimal series mineral wool. Among its characteristics, it should be noted low compressibility under a specific load of 2 kPa - 10%. The density of the Isover Standard slabs is 50 kg / m3.

Isover Venti

This product is intended for thermal insulation of ventilated facades, and there is no limitation on the height of the building. This is achieved by the fact that this material has a high mechanical strength. It is also produced in slabs of 60-100 cm in size with a thickness of 5 or 10 cm. The density of the material is 85 kg / m3. Due to its high vapor permeability, moisture effectively escapes from the structure. Like other mineral wool materials, Izover Venti does not burn.

Izover for ventilated facades

The model range of Izover Venti Optimal has slabs with a thickness of 3 to 20 cm. This allows you to choose the most suitable solution for each insulated facade.

Izover Facade

This range is used to insulate plaster facades. If stone plaster is chosen as the finish and the insulation will need to be covered with a thin layer of plaster, then this option must be chosen. The thickness of the produced slabs ranges from 5 to 20 cm, width - 60 cm, length - 100 cm.

Density characteristic of Izover Plaster Facade - 145 kg / m 3. For a simplified and accelerated installation of such plates on the surface of the walls, this material is produced with other geometric dimensions - 60 * 120 cm.

Isover for plaster facades

Isover Light

It is used in various fields - interior partitions, suspended ceilings, ventilated facades and frame structures. Izover Light has increased elastic properties of the slab. The density of the material is 38 kg / m³. During operation, it does not undergo shrinkage or deformation.

Isover Classic

It is used for thermal insulation of floors and ceilings and is laid between the joists. Isover Classic is produced in rolls, and during transportation the mineral wool is compressed 6 times. Density - 11 kg / m 3. The width of the roll is 122 cm, in it the material is folded into two layers of 5 cm each, so during installation it is easy to choose the required thickness of the insulation. Since the width between the joists can be 60 cm, the mats are cut lengthwise into two pieces of 61 cm wide and fit tightly between the boards.

Thermal insulation of floors

Isover Sauna

This model also has a vapor barrier. The presence of a foil layer makes it possible to save the high temperature of the sauna for a long time.It will also save time on installation work, since two stages are performed at once and there is no need to install additional films or membranes. The thickness of Izover Sauna is 50 or 100 mm. It is used to insulate not only walls, but also ceilings in baths.

Izover Master of Acoustics

It is used wherever acoustic insulation is required. It comes in the form of stone fiber based mineral wool slabs. It is used for external walls, interior partitions, floors and ceilings, that is, wherever high-quality sound insulation by Izover Master may be needed.

Isover Flor

Such insulation is used to protect against impact noise. It reduces the noise level by 35 dB. Isover Flor is produced by the manufacturer in the form of rigid slabs with dimensions of 60 * 120 cm and a thickness of 3-5 cm.

Isover Profi

This is the warmest material among analogues. It is produced in rolls and is used in many inclined structures, for example, for roof insulation, plasterboard partitions on a metal frame. Izover Profi is also used before finishing the facade with siding or facing bricks. The thickness of the rolls is 5, 10 or 15 cm. The roll length is 4-5 meters.

There are other varieties of this insulation. Thanks to this variety, you can choose the most suitable material for high-quality performance of thermal insulation work. You can also choose the thickness and dimensions of the insulation. Correctly carrying out all the work, you can significantly save heating costs and provide comfortable conditions in the room.

Today, isover optimal insulation is very popular among a huge layer of people. People are going to buy isover optimal insulation, as it has an amazing number of well-known features, among which it is necessary to emphasize the ease of installation, low price and effective protection from the cold. Isover optimal insulation is simply irreplaceable in the design and creation of heat-insulating coatings for walls and roofs of premises. It does not get wet and does not rot, and is not able to absorb moisture. Mold and rot are also not terrible for such a material as isover optimal insulation, since it has the necessary impregnation.

Insulation isover optimal: application and use

Where can Isover Optimal be used? Walls, roof slopes, ceilings - all these parts of buildings and apartments simply cannot be effectively insulated without the described material. It has good flexibility, and installers can easily change its size and shape, depending on the wishes of the client. Floor slabs are also often protected with this material.

Advantages and disadvantages - isover optimal insulation

Let's designate the greatest distinguishing features that the isover optimal insulation can boast of. Of course, the main quality, which is why isover insulation is optimal and is known, is its efficiency in keeping warm. Complete sealing of the building with heat loss is an obvious result of the use of isover optimal insulation. In addition, the isover optimal insulation is completely environmentally friendly: it is non-flammable and does not form harmful substances. During production, to achieve these goals, certain types of additives are used that make the isover optimal insulation safe. In addition, this material completely deprives you of sounds from the street. You are also not in danger of mold because of the water-repellent qualities of this material and its structure. In addition, the isover optimal insulation is coated with bactericidal additives that prevent fungi and mold from appearing.

Izover facade light density

Description

ISOVER Facade Light are rigid heat and sound insulation boards made of mineral wool based on quartz. Specially adapted for use as part of facade systems with a thin plaster layer in low-rise buildings. The material ensures the reliability and durability of plaster facades.

Thermal insulation layer in the structures of thin-layer plaster facades for cottage and low-rise construction

- The only rigid fiberglass slabs: strong, lightweight, easy to install

- Reliable thermal protection of your home due to the low thermal conductivity λ = 0.037 W / m * K

- Professional solution specially adapted for private housing construction

- Safe for human health and the environment: allowed for use in kindergartens and preschool institutions

- Fire safety: belongs to the group of non-combustible materials (NG)

PLATE GEOMETRIC DIMENSIONS AND PACKING STANDARDS

| Material name | Length, mm | Width, mm | Thickness, mm | Packing, pieces (plates) | Packing, m 2 | Packing, m 3 |

| Facade Light-50 | 1200 | 600 | 50 | 8 | 5,76 | 0,288 |

| Facade Light-100 | 1200 | 600 | 100 | 3 | 2,16 | 0,216 |

| Facade Light-150 | 1200 | 600 | 150 | 2 | 1,44 | 0,216 |

INSTALLATION RECOMMENDATIONS FOR SFTK WITH THIN PLASTERING LAYERS

- Heat-insulating plates are fixed to the base from the bottom up, starting from the support (basement) profile.

- Before applying the adhesive, it is recommended to prime the surface of the thermal insulation board with a thin layer of the same adhesive.

- Thermal insulation boards are attached to the base of the wall with an adhesive and additionally fixed with disc anchors.

- The contact area of the adhesive with the base after the installation of the thermal insulation board in the design position must be at least 40%.

- After applying the adhesive, the slab is immediately installed in the design position, the excess of the protruding composition is removed. The correctness of the installation of each heat-insulating plate in the design position is controlled by a level of 2 m long.

- Installation of thermal insulation boards should be carried out close to each other. If, after installing the plates, gaps with a width of more than 2 mm remain, they must be filled with a uniform layer of heat-insulating material.